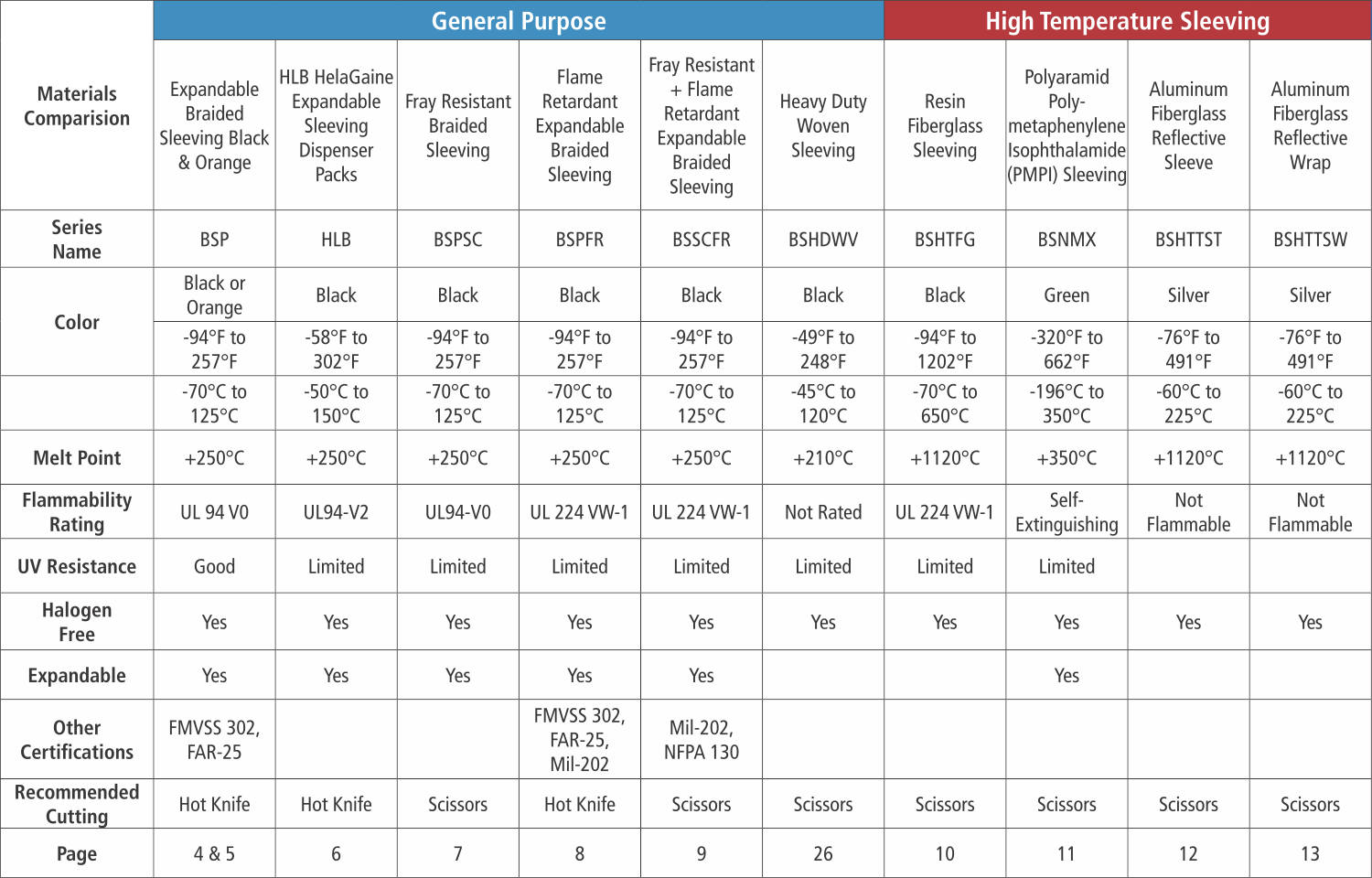

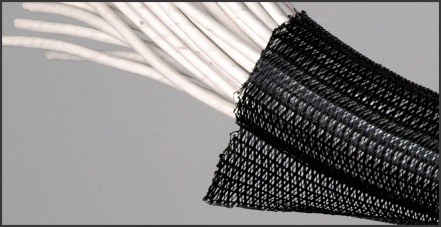

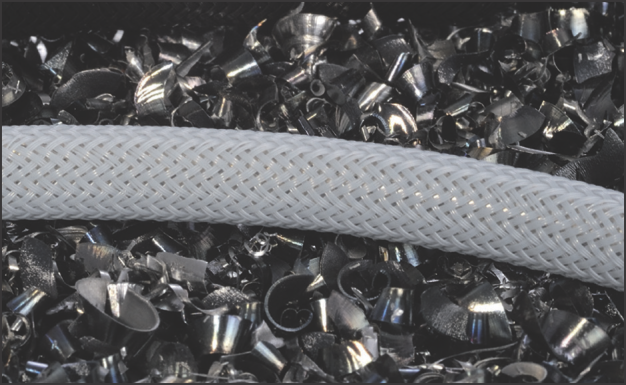

HellermannTyton braided sleeving products provide abrasion and damage protection for hoses, cable assemblies and wire bundles. Braided sleeving products are made in a variety of materials including general purpose polyester, PA66 nylon, flame retardant, fray resistant, high temperature and materials that provide electromagnetic protection.

Available in non-expandable, expandable, split wrap and hook and loop styles, HellermannTyton offers a braided sleeving option for every application. Many sleeving products are also resistant to harsh environments such as chemicals, salts, solvents, de-icing fluids and petroleum products as well as being resilient against UV light. The unique physical weave of braided sleeving makes it flexible but provides enough airflow as to not trap moisture or humidity. Expandable braided sleeving products are designed to expand beyond their nominal size to fit varying bundle sizes and shapes.

Most braided sleeving products are designed to be cut with a hot knife, which sears the edges and reduces the amount of fraying that occurs during the lifetime of the product. For applications that do not allow access to a hot knife, fray resistant versions are available that can be cut with ordinary scissors with minimal fraying. Ends are easily secured with cable ties, electrical tape or heat shrink materials.

Market Applications

Automotive, Transportation, Industrial Equipment, Electronics, Automation/ Robotics, Control Panels, Marine, Machine Tools, General Manufacturing/OEM

Product Applications

Hose Assemblies, Cable Bundles, Wire Harnesses, Electrical Cables

Key Benefits

Easy Application

All braided sleeving products are designed for easy application on bundles while adjusting to fluctuations in bundle size and shape.

Superior Protection

In addition to abrasion protection, most braided sleeving products also provide protection against chemicals, salts, solvents, de-icing fluids and petroleum products. Specialty braided sleeving models also provide protection against flame, heat and/or electromagnetic interference.

Enhanced Appearance

Braided sleeving products wrap around varying bundle shapes, sizes and colors to provide an aesthetically pleasing uniform look and appearance.

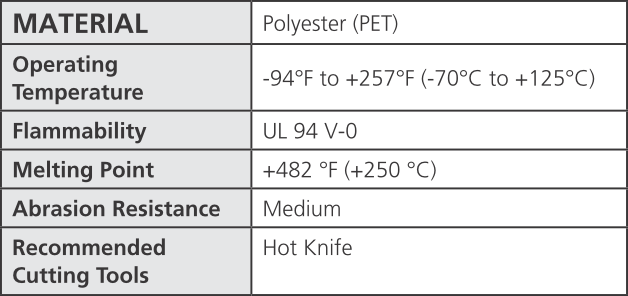

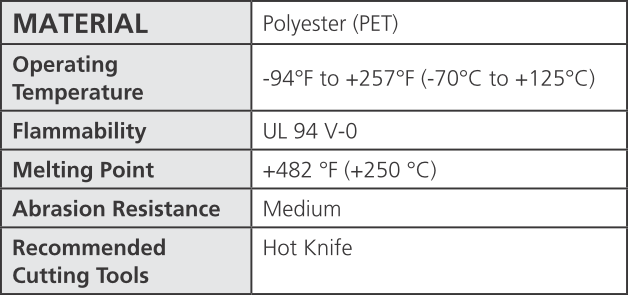

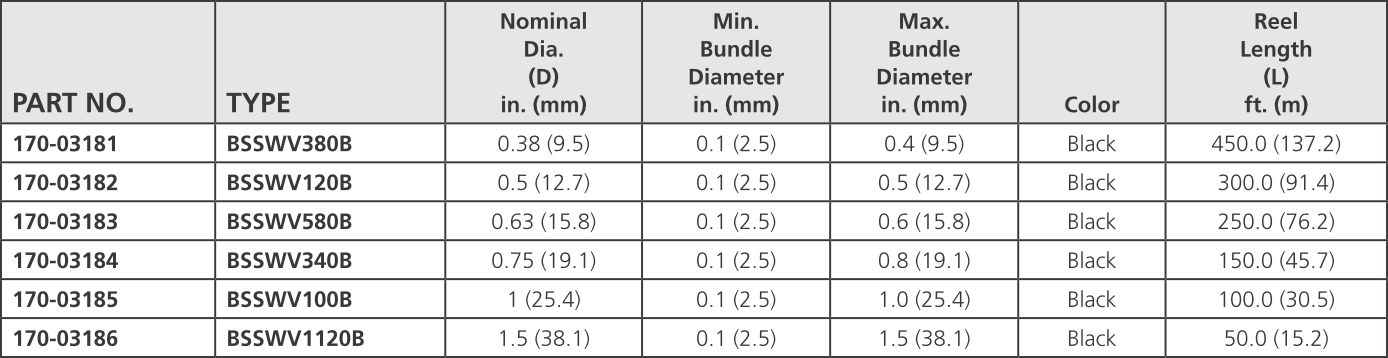

Braided Sleeving - General Purpose

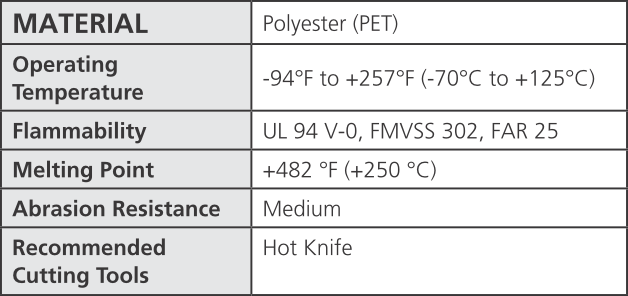

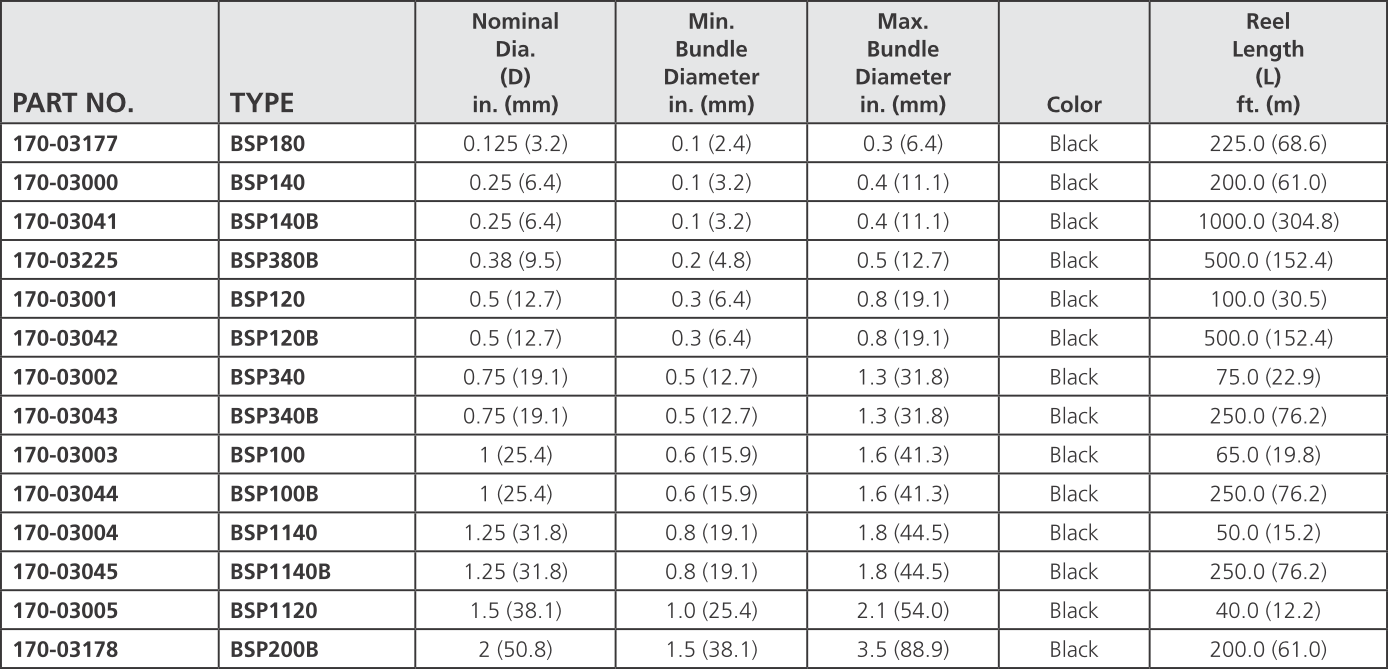

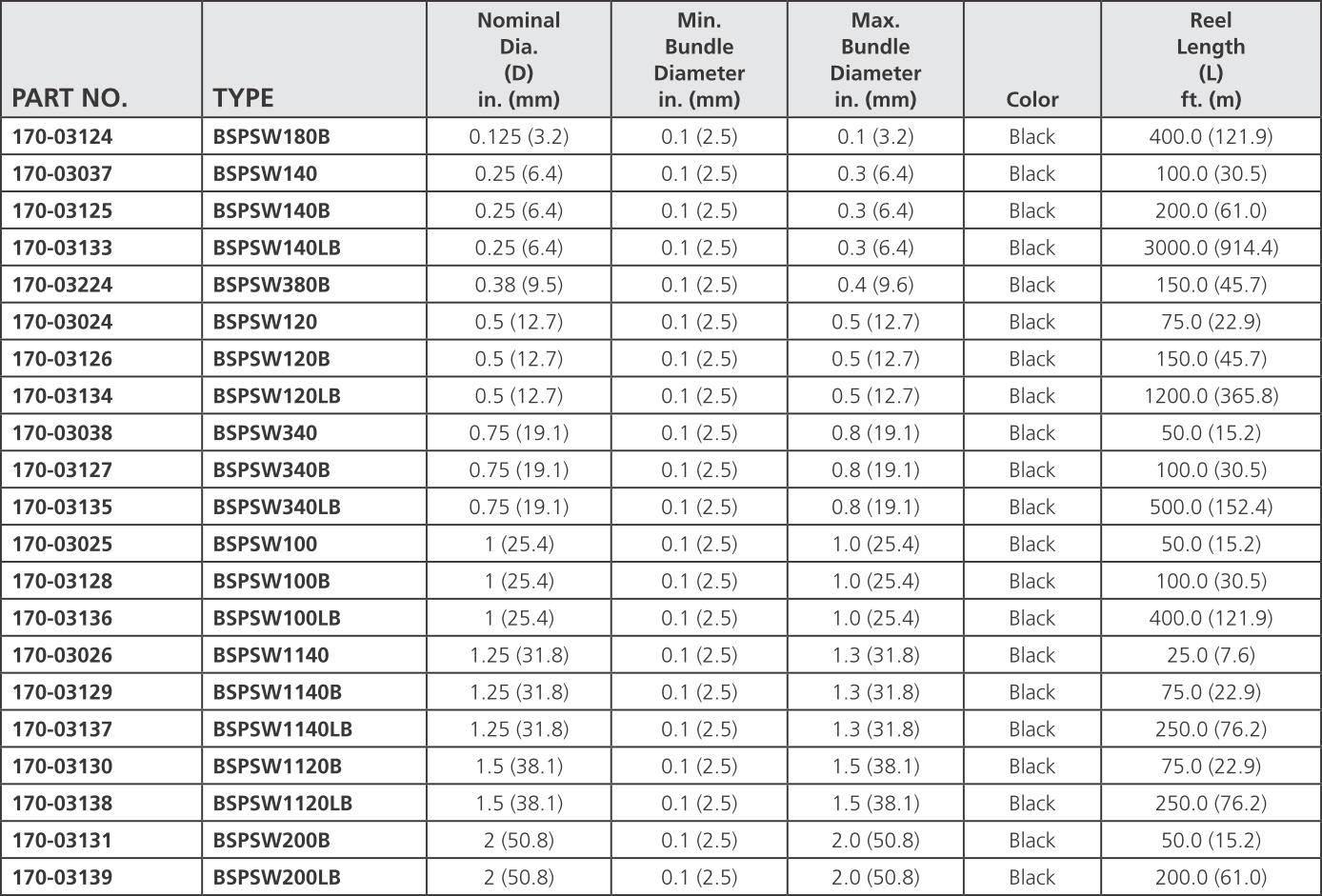

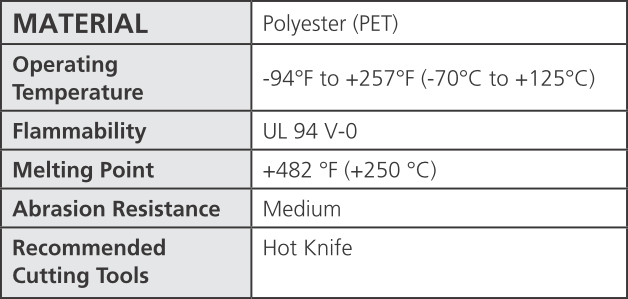

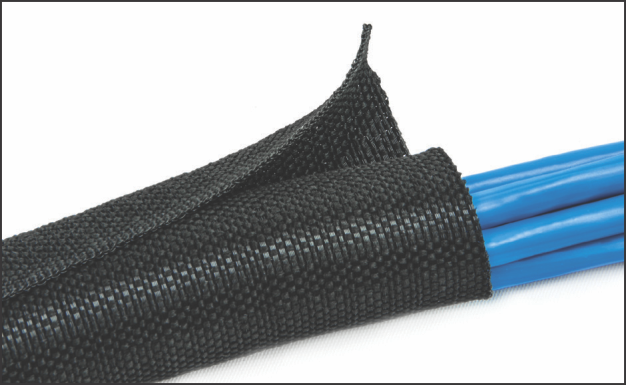

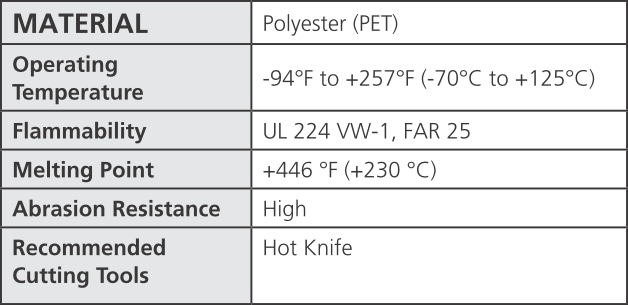

Expandable Braided Sleeving - Black

Designed to adjust and expand to irregular shapes, this general purpose sleeving is lightweight and offers a high tensile strength while still maintaining flexibility. This sleeving is an excellent choice for protecting wire and cable bundles from abrasion, chafing and heat degradation. Commonly used in electrical and industrial wire harnessing application where economy and durability are required for the protection of wires, cables, tubing, bundles and pneumatic hoses.

Features and Benefits

Braided Sleeving - General Purpose

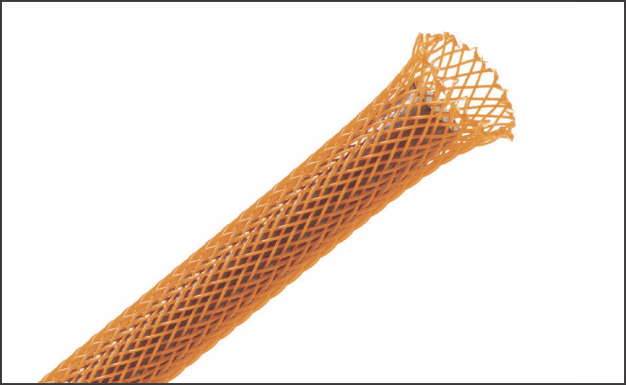

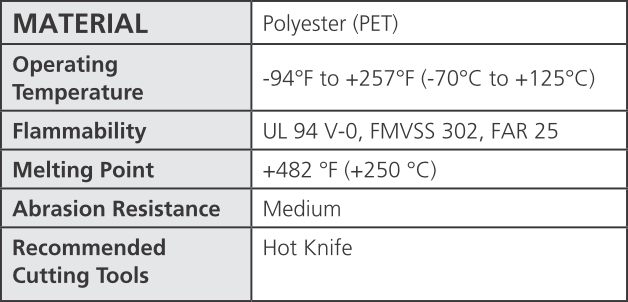

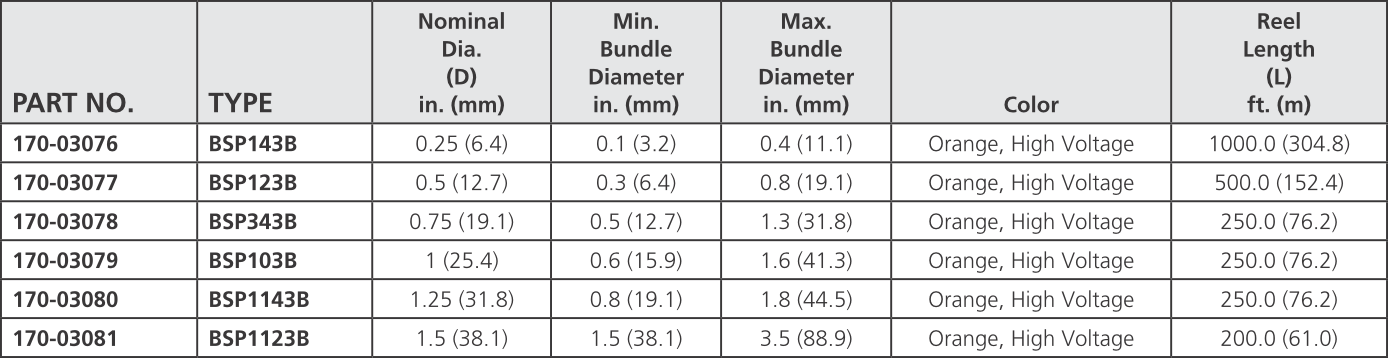

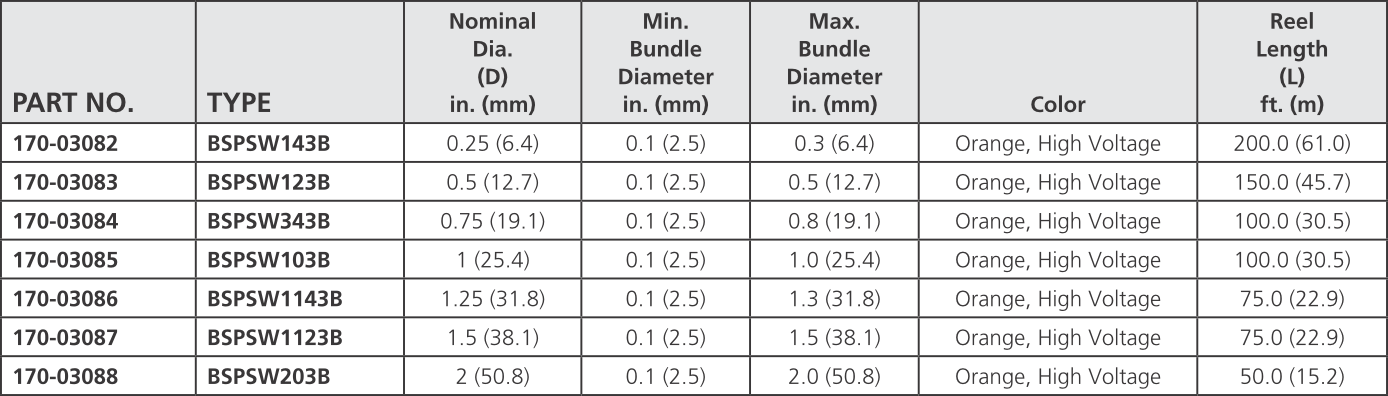

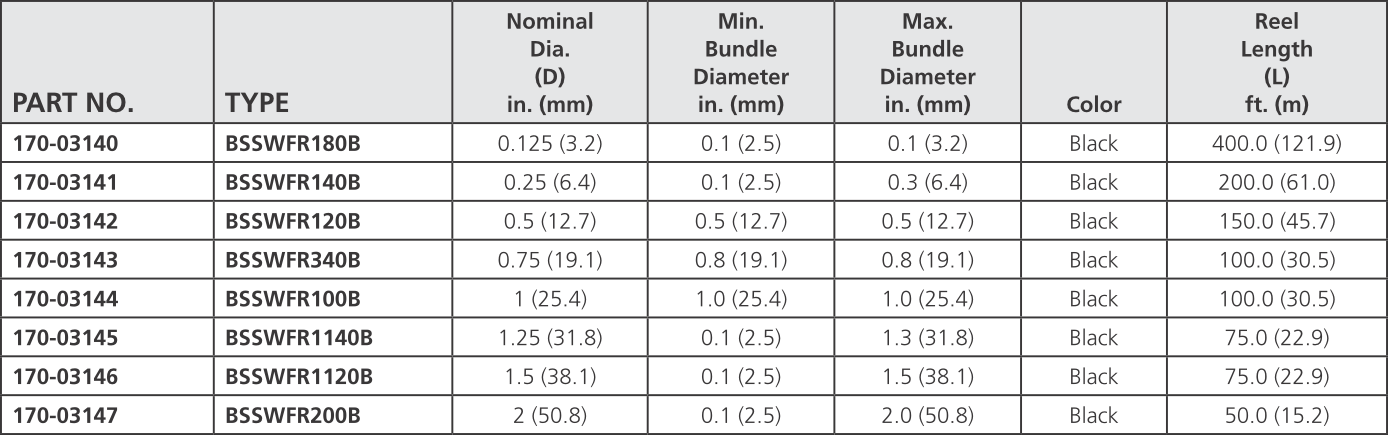

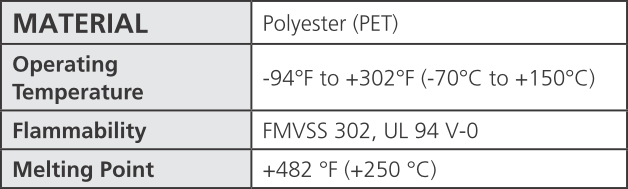

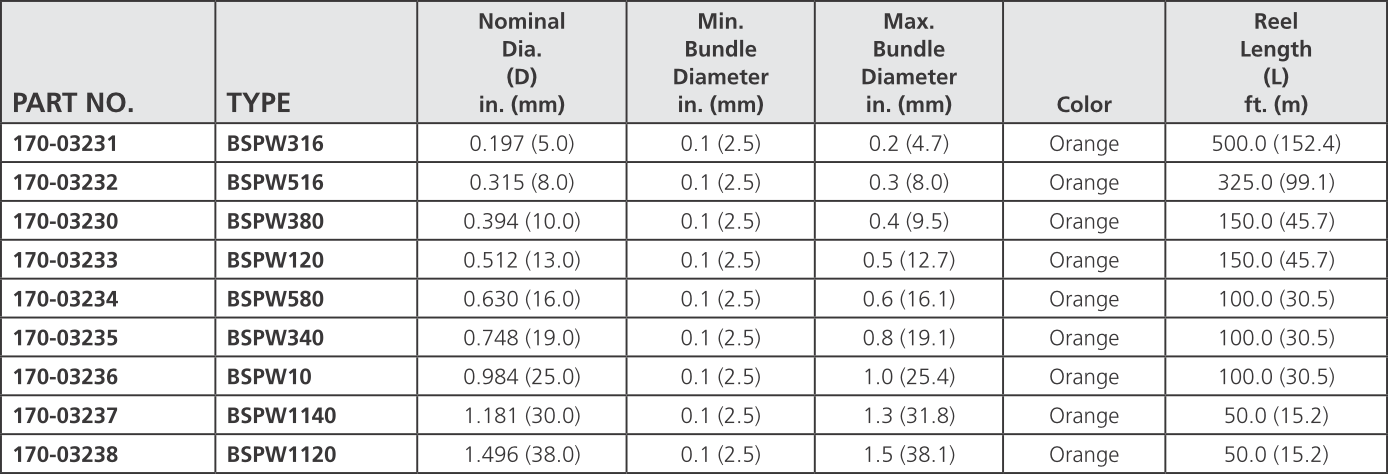

Expandable Braided Sleeving - Orange

Orange PET braided sleeving is an extremely flexible, general purpose option for bundling and protecting wires and cables in abrasive type applications. Its color makes it ideal for systematic color coding of complex wiring installations. Commonly used to shield cable harnesses in battery powered vehicles, such as hybrid cars, golf carts and light trucks.

Features and Benefits

Braided Sleeving - General Purpose

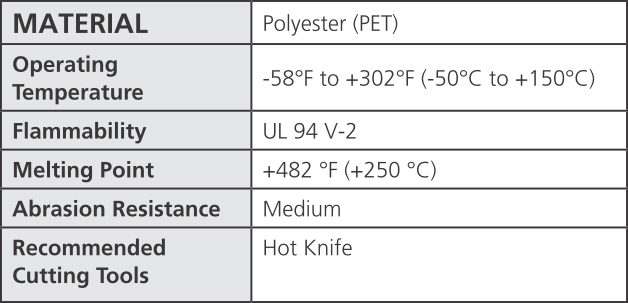

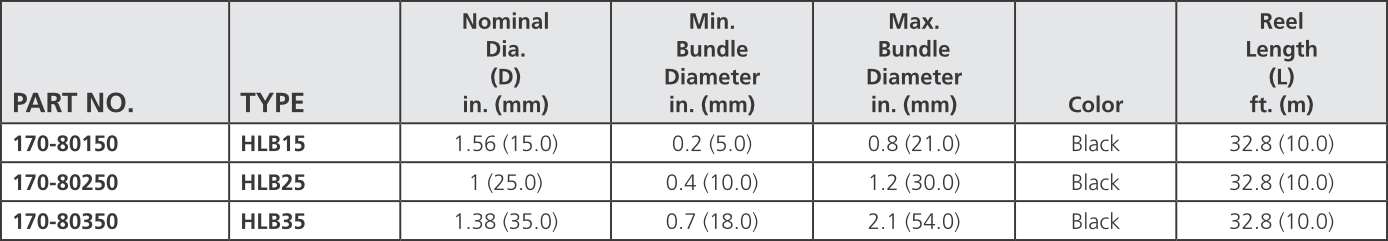

Expandable Braided Sleeving - Helagaine Dispenser Packs

This convenient package holds mini spools of expandable braided sleeving. Designed to save space and provide easy acess when dispensing, this unit allows for the efficient handling and management of sleeving. The perfect solution for use in field-service applications where a large spool of braided sleeving is not feasible or when only a small amount of sleeving is required for a quick-fix project.

Features and Benefits

Braided Sleeving - General Purpose

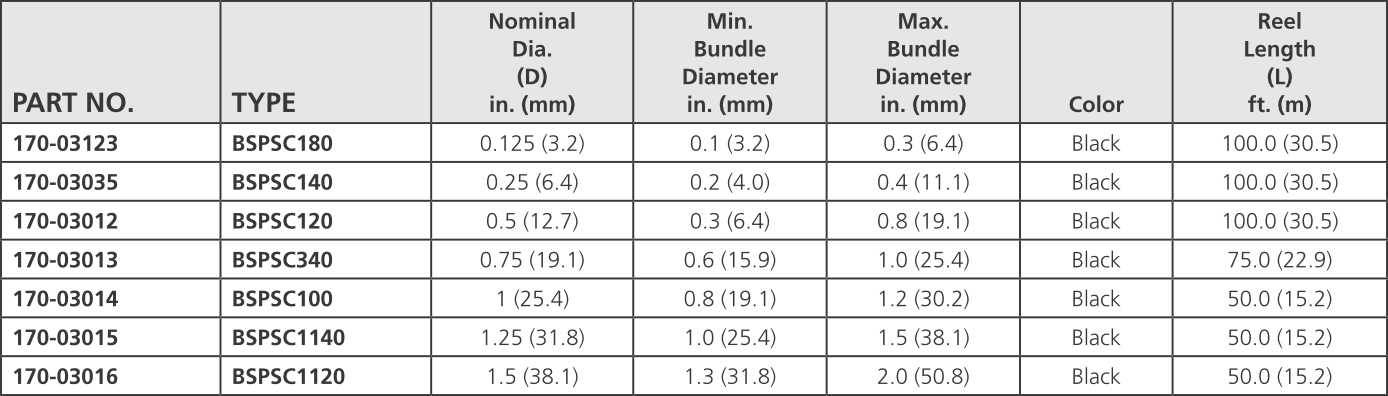

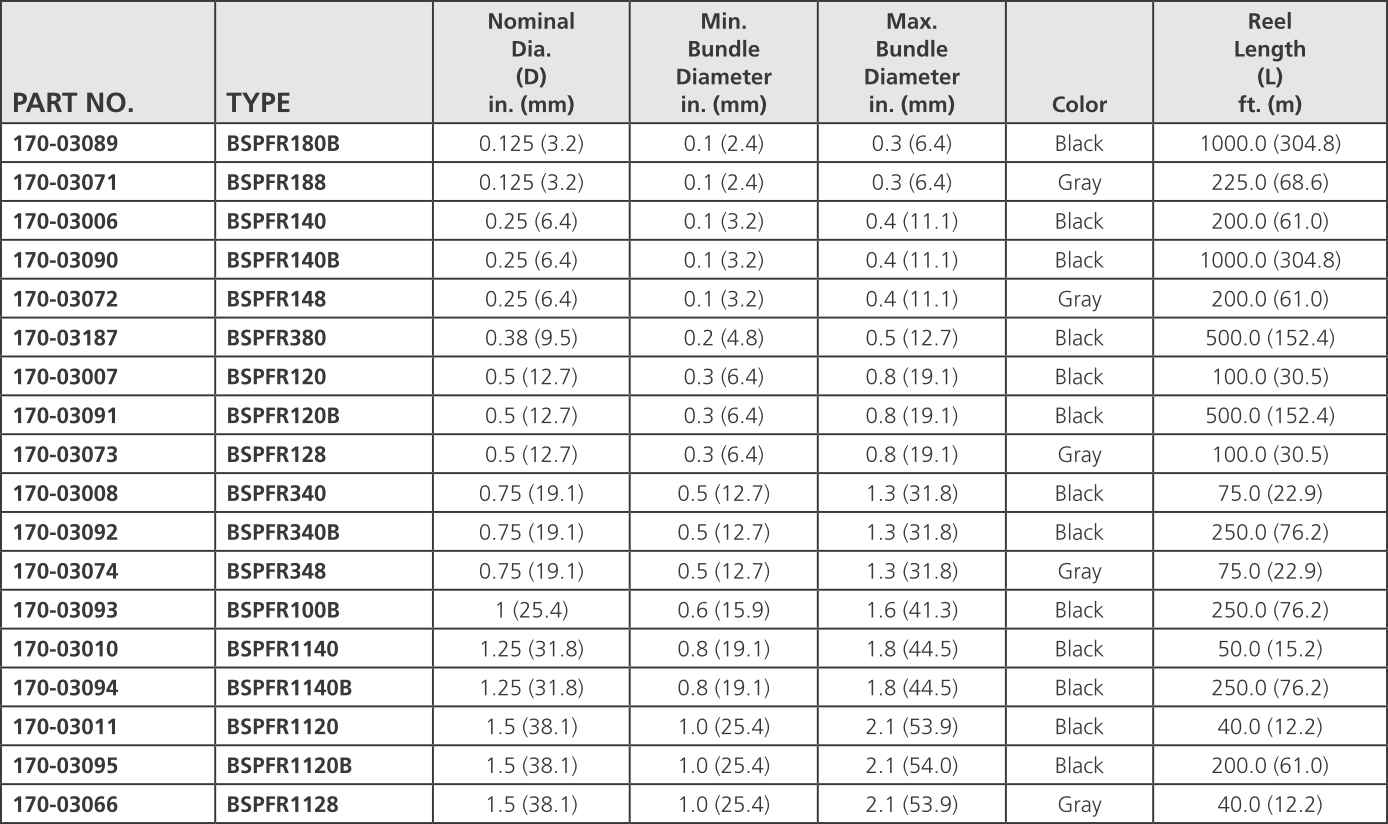

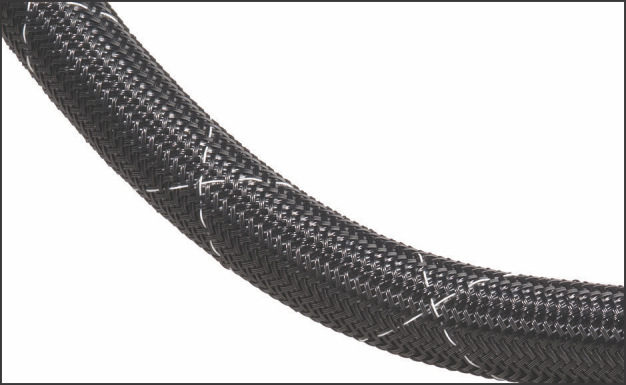

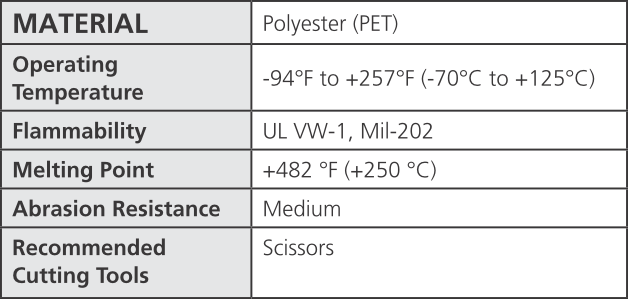

Fray-Resistant Expandable Braided Sleeving

A versatile and economical general-purpose sleeving that resists fraying when cut with ordinary scissors. For use in automotive, industrial and computer applications where the wires, cables and hoses being covered endure frequent handling. It is suited for situations where access to a hot knife is either impractical or impossible.

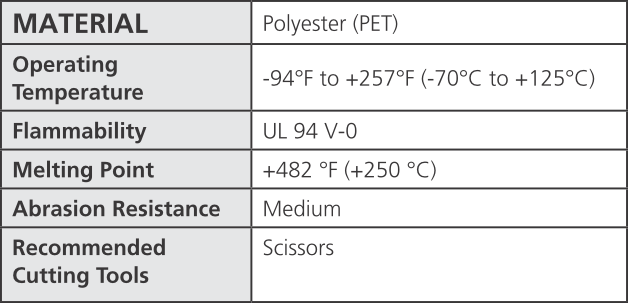

Features and Benefits

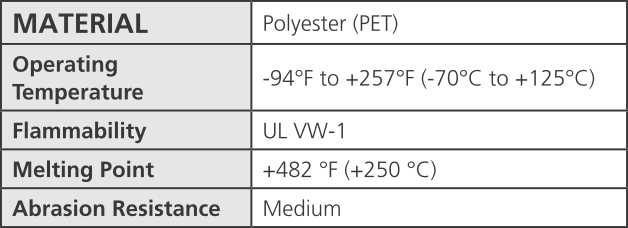

Braided Sleeving - Flame Retardant

Expandable Braided Sleeving - Treated PET

A flame retardant woven (threaded) polyester sleeving that is resistant to cuts and abrasion, and contains a combustion inhibitor allowing it to achieve a UL and CSA flame resistance rating of VW-1. Contains white tracer thread for easy identification.

Features and Benefits

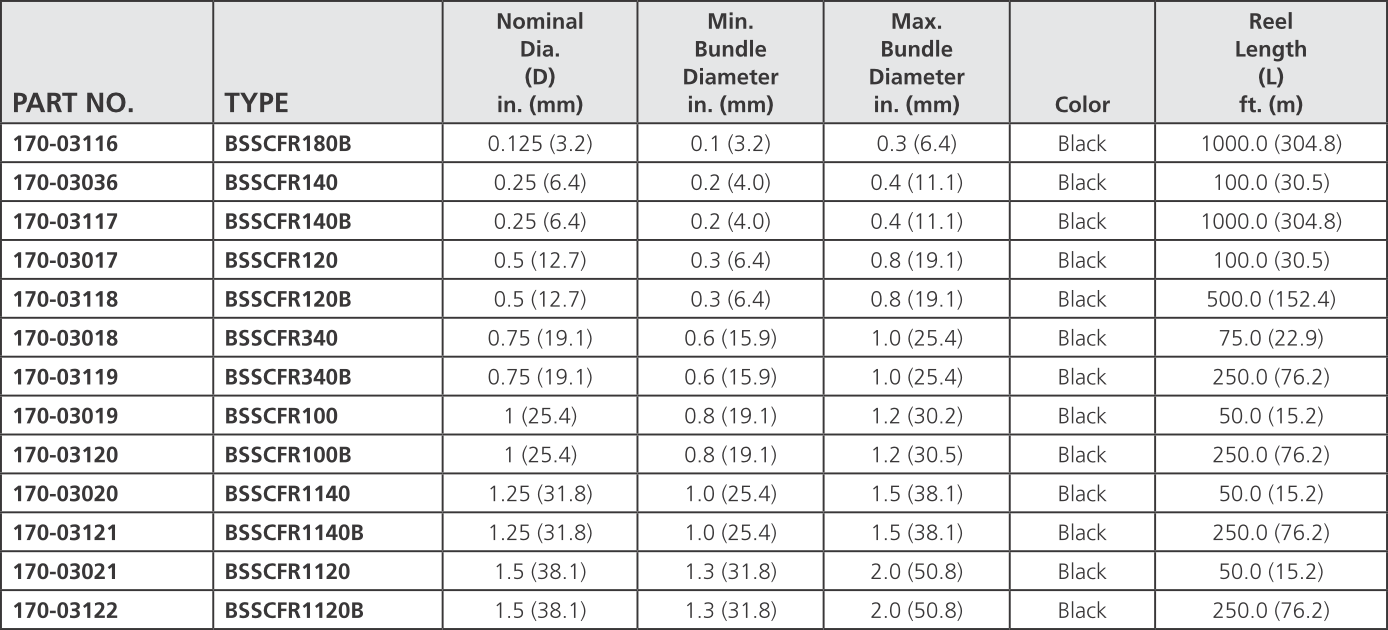

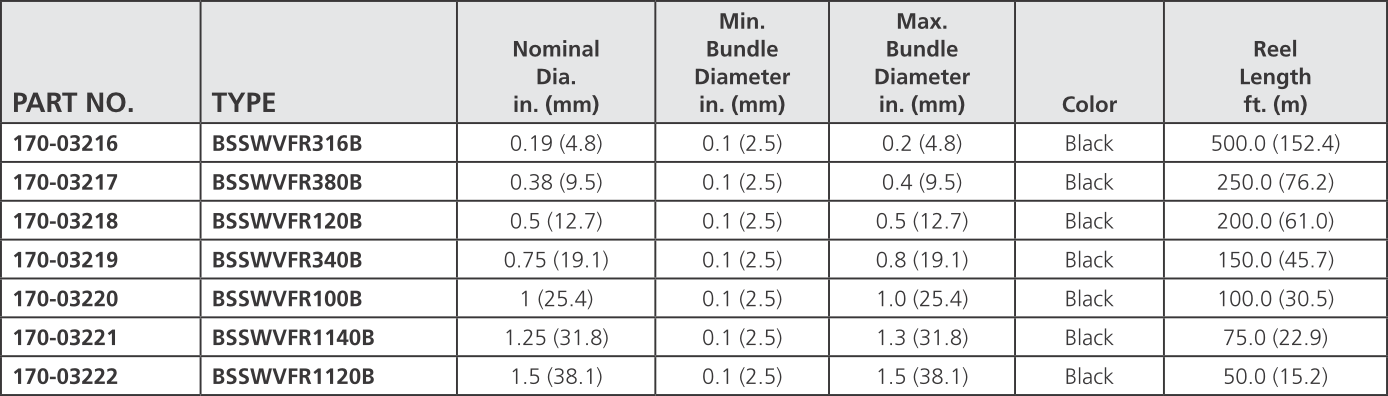

Braided Sleeving - Flame Retardant

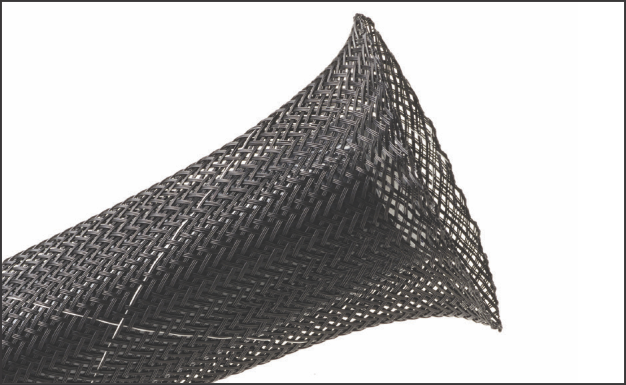

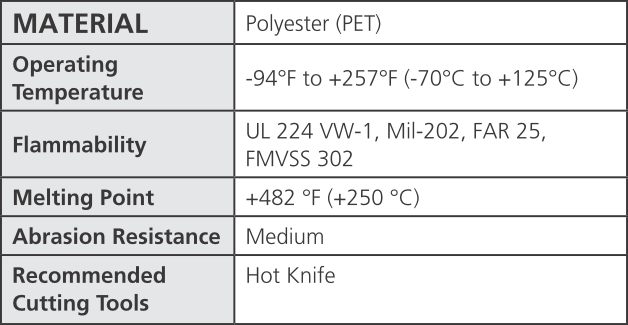

Fray Resistant Expandable Braided Sleeving

This protective sleeving is self-extinguishing and can be cut with sharp scissors instead of a hot knife for fray-resistant ends. Readily used in the automotive, audiovisual, industrial, wire, cable and computer industries where flame retardancy is required to reduce the likelihood of ignition and/or reduce the rate of flame spread. It is suited for situations where access to a hot knife is either impractical or impossible.

Features and Benefits

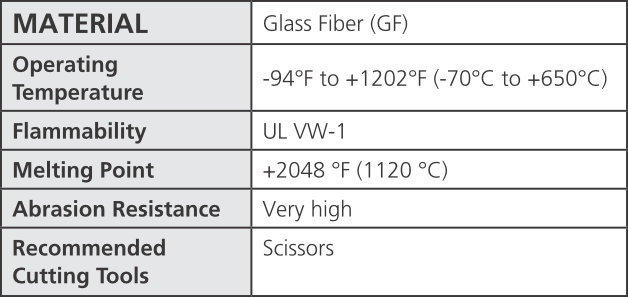

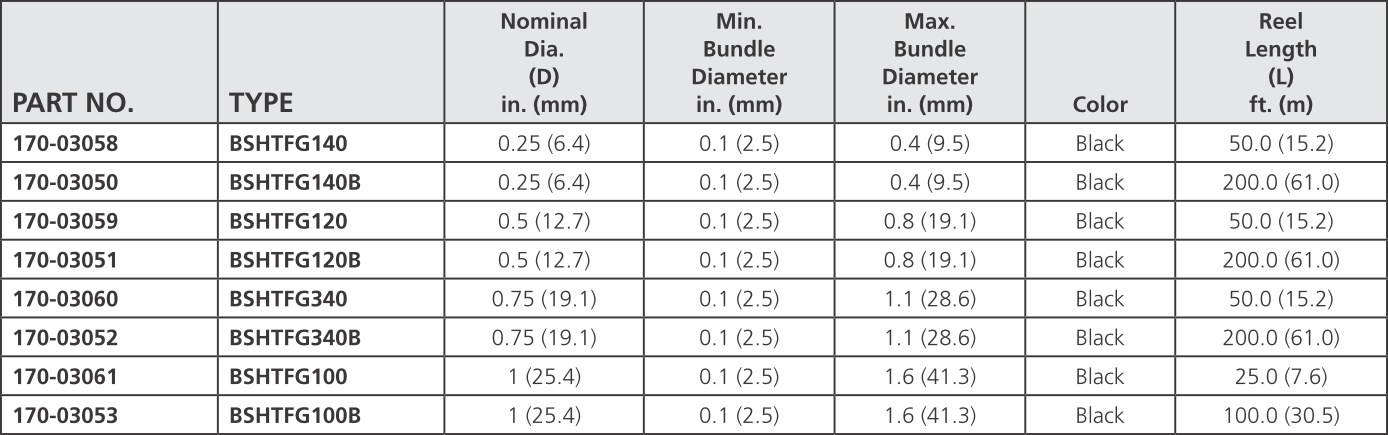

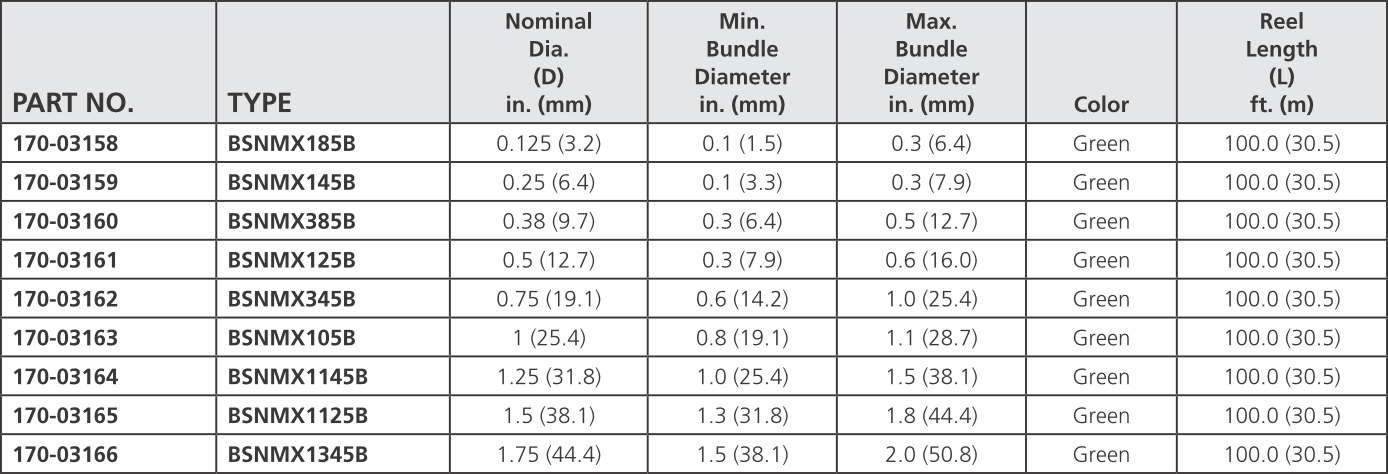

Braided Sleeving - High Temperature

Extreme High Temperature Resin Saturated Fiberglass Braided Sleeving

An extremely high-temperature resistant sleeving designed to protect wires and cables subjected to continuous temperature variations, vibration, abrasion, and mechanical stress. Perfect for engine manifolds and exhaust systems or any application where fire and extreme temperatures create a hazard to workforce and equipment.

Features and Benefits

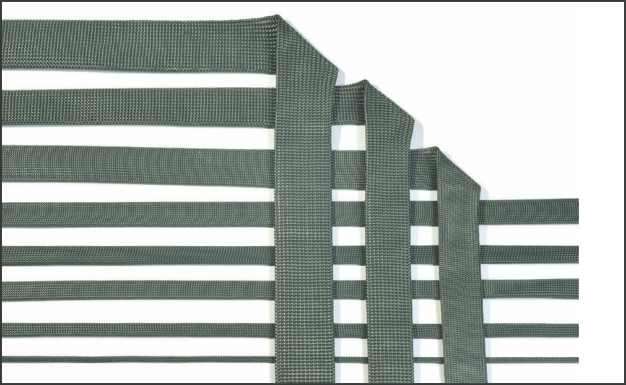

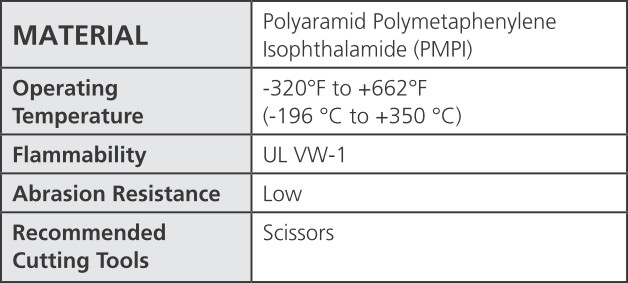

Braided Sleeving - High Temperature

High Temperature Nomex® Expandable Braided Sleeving

A densely woven aramid fiber sleeving, this soft and flexible material is self extinguishing and can withstand temperatures reaching up to 662°F. Excellent for use in extremely harsh environments including those with exposure to direct flame, high temperatures, as well as Beta, Gamma and X-Ray radiation - in particular, military and aerospace wiring and harnessing applications.

Features and Benefits

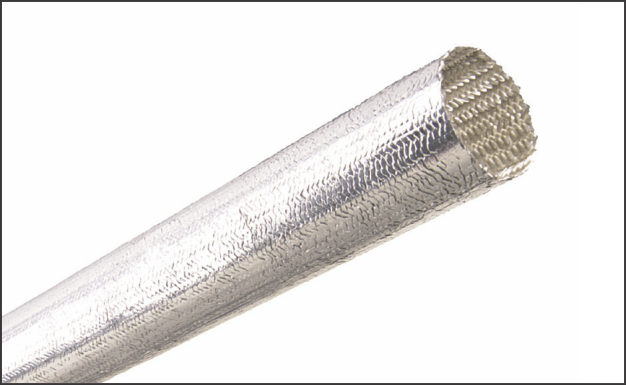

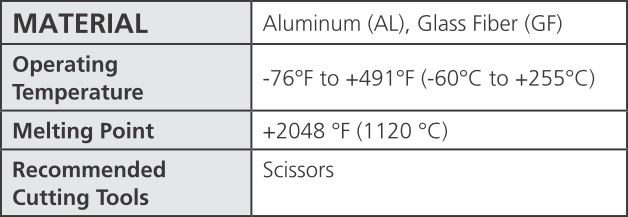

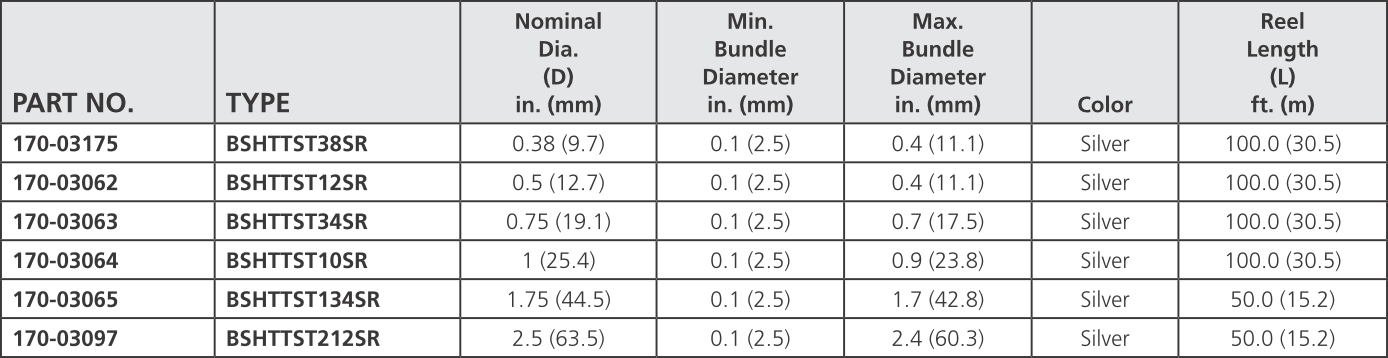

Braided Sleeving - High Temperature

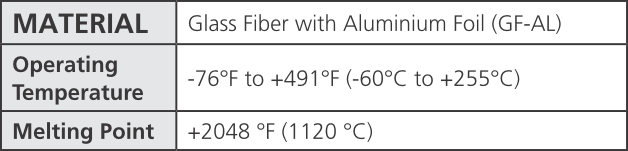

High Temperature Aluminum Laminated Fiberglass - Sleeves

High Temperature Aluminum Laminated Fiberglass Sleeving is a tubular-shaped product that combines the protection of bonded aluminum and fiberglass into a single solution that is able to reflect radiant heat away from the sensitive contents inside the tube.

Features and Benefits

Braided Sleeving - High Temperature

High Temperature Aluminum Laminated Fiberglass Wraps

Aluminum Laminated Fiberglass Wrap sleeving combines the protection of bonded aluminum and fiberglass into a robust solution that deflects radiant heat away from sensitive wires and cables. Wrap-around design allows for fast and easy installation and maintenance. Sold in 4-foot sticks.

Features and Benefits

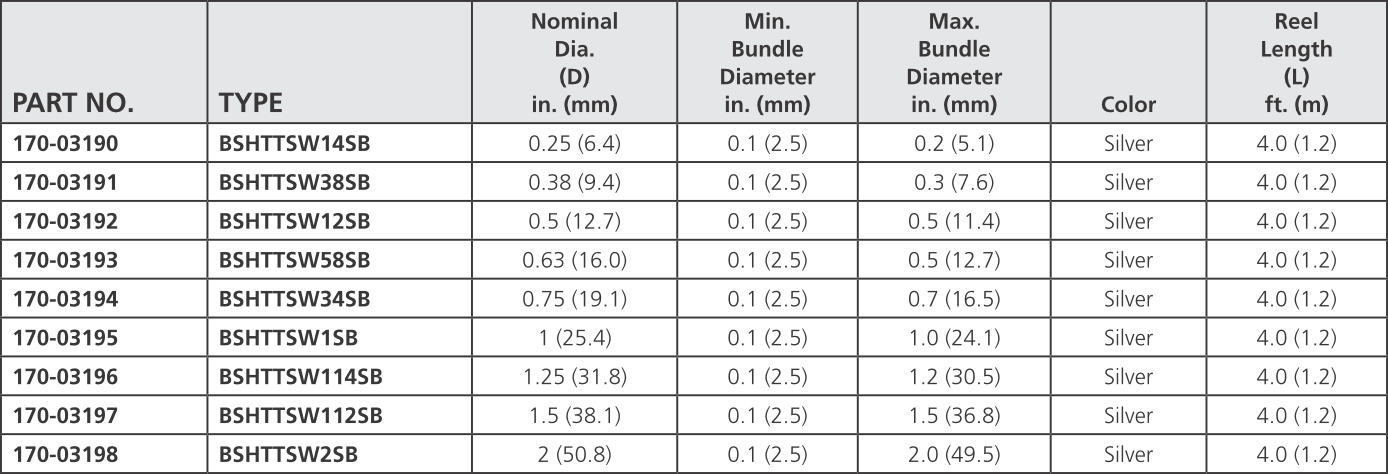

Braided Sleeving - Wraps

Split Wrap Braided Sleeving - Black

A bundling and protection option with a lateral split and a semi-rigid braid configuration that is the ideal solution for circumstances where ease of installation is the primary concern. The lateral split allows the sleeving to open to adjust to the bundling requirement while the 25% edge overlap folds back over to protect the connector or splices. More flexible than spiral wraps or convoluted tubing, this product is a fast and easy option for adding protection in post-assembly or post-installation situations.

Features and Benefits

Braided Sleeving - Wraps

Braided Sleeving - Split Wrap

Used for safety identification, this bundling and protection option also offers a lateral split and a semi-rigid braid configuration that wraps around the bundle assembly without requiring fasteners, such as hook and loop, cable ties or tape.

Features and Benefits

Braided Sleeving - Wraps

Split Wrap Woven Braided Sleeving

Split Wrap Woven Sleeving is a self-closing sleeving manufactured from a unique blend of monofilament and multifilament polyester fibers that resemble a tightly woven material. The wrap around design provides increased flexibility, better coverage and greater resistance from abrasion for wires, cables and assemblies. Can also be used to reduce noise in applications that involve movement, while protecting sensitive electronics and communication systems from dust and debris.

Features and Benefits

Braided Sleeving - Flame Retardant

Split Wrap Expandable Braided Sleeving

A lateral split, semi-rigid and flame retardant braided sleeving configuration used when ease of installation and repeat access to wire bundles is required. The lateral split allows the sleeving to open and accommodate a variety of bundling requirements. The 25 percent edge overlap rolls back over connectors and splices without exposing the bundled wires. More flexible than spiral wraps or convoluted tubing, this product is a fast and easy option for adding protection in post-assembly or post-installation applications. Meets NFPA 130 rail market applications.

Features and Benefits

Braided Sleeving - Flame Retardant

Split Wrap Braided Sleeving

Used when flame retardancy is a primary requirement, this protection option incorporates a lateral split which allows the tube to open up to accommodate a variety of bundling requirements. The semi-rigid braid configuration simply closes around the entire installation without the need for any additional fasteners. Split wrap flame retardant braided sleeving is self-extinguishing and complies with UL VW-1 standards where cables exit a wall and need to be managed for an uncluttered, clean appearance.

Features and Benefits

Braided Sleeving - Wraps

Self Wrapping Woven Braided Sleeving - Orange

Split Wrap Woven Sleeving is a self-closing sleeving manufactured from a unique blend of monofilament and multifilament polyester fibers that resemble a tightly woven material. The wrap around design provides increased flexibility, better coverage and greater resistance from abrasion for wires, cables and assemblies. Can also be used to reduce noise in applications that involve movement, while protecting sensitive electronics and communication systems from dust and debris.

Features and Benefits

Braided Sleeving - Wraps

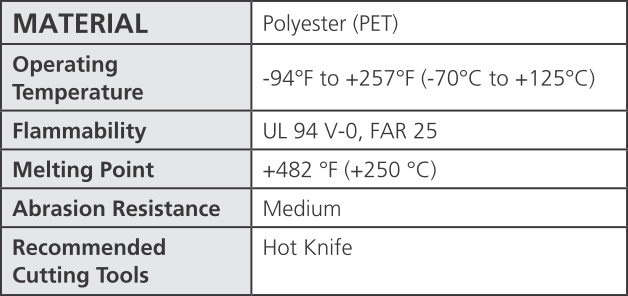

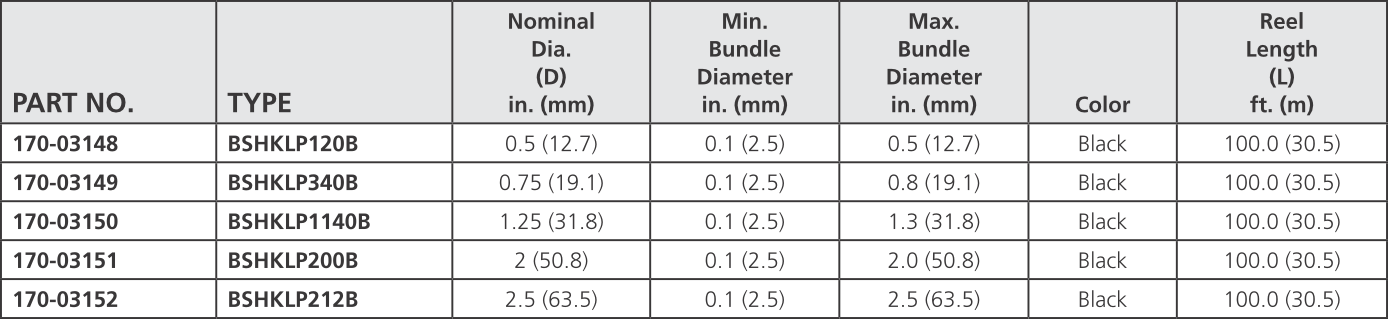

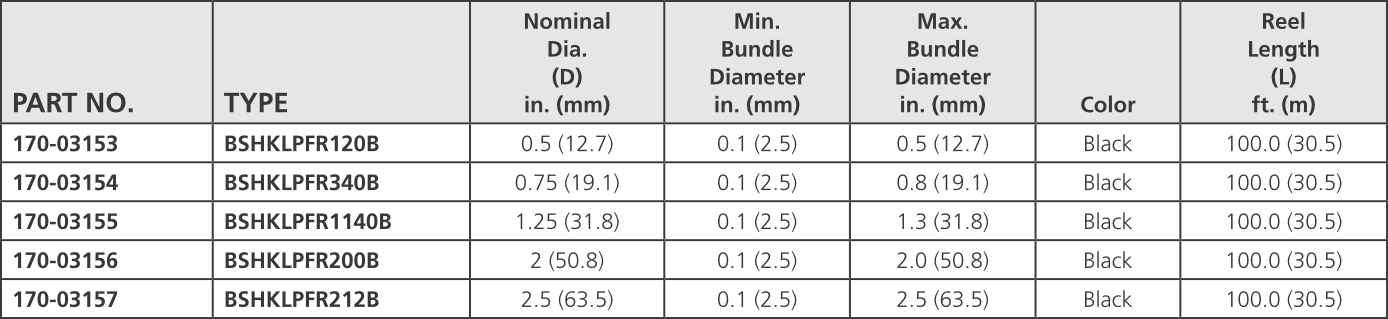

Hook and Loop Expandable Braided Sleeving

Designed for the quick and easy management of wires, this expandable sleeving has an internal hook and loop strap that is able to adhere to its outer PET braid, delivering flexibility that allows it to fit around odd-shaped connectors. Its color-matched hook and loop closure provides for an easy on and off installation, as well as instant and convenient access for harness break-outs and networks. The primary application for this sleeving is the wrapping and bunching of cables in a deployed situation or when frequent access to cables is necessary.

Features and Benefits

Braided Sleeving - Flame Retardant

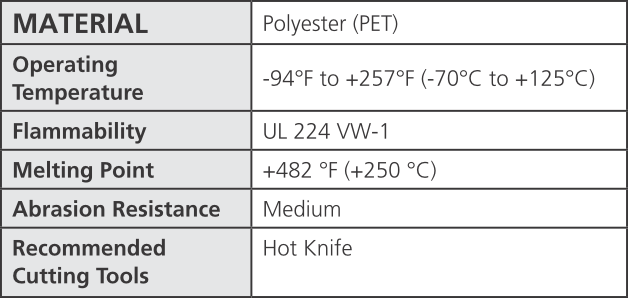

Hook and Loop Expandable Braided Sleeving

Flame retardant expandable braided sleeving with hook and loop strip for wrapping around cable assemblies. Color matched hook and loop closure provides an easy on and off installation, as well as convenient access for harness breakouts and when maintenance is necessary. Material is self-extinguishing and complies with UL VW-1 standards.

Features and Benefits

Braided Sleeving - Specialty

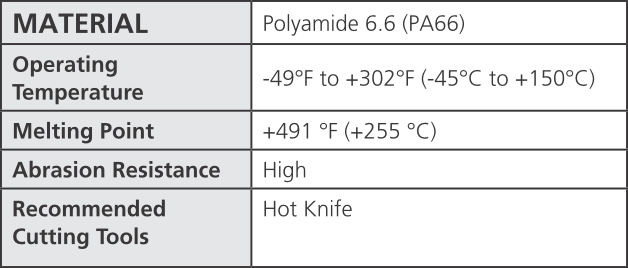

Polyamide 6.6 Expandable Braided Sleeving - Black

A pliable yet durable nylon sleeve that protects against cuts, abrasion and excessive wear caused by repetitive motion. Used on hoses, pipes, wiring harnesses and cables installed in cars, trucks, military vehicles, trains and industrial equipment. Protects delicate wiring in engine compartments and near exhaust systems or used to organize wires and breakouts in electrical harnesses.

Features and Benefits

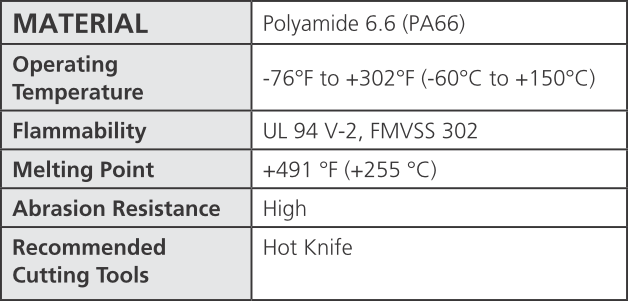

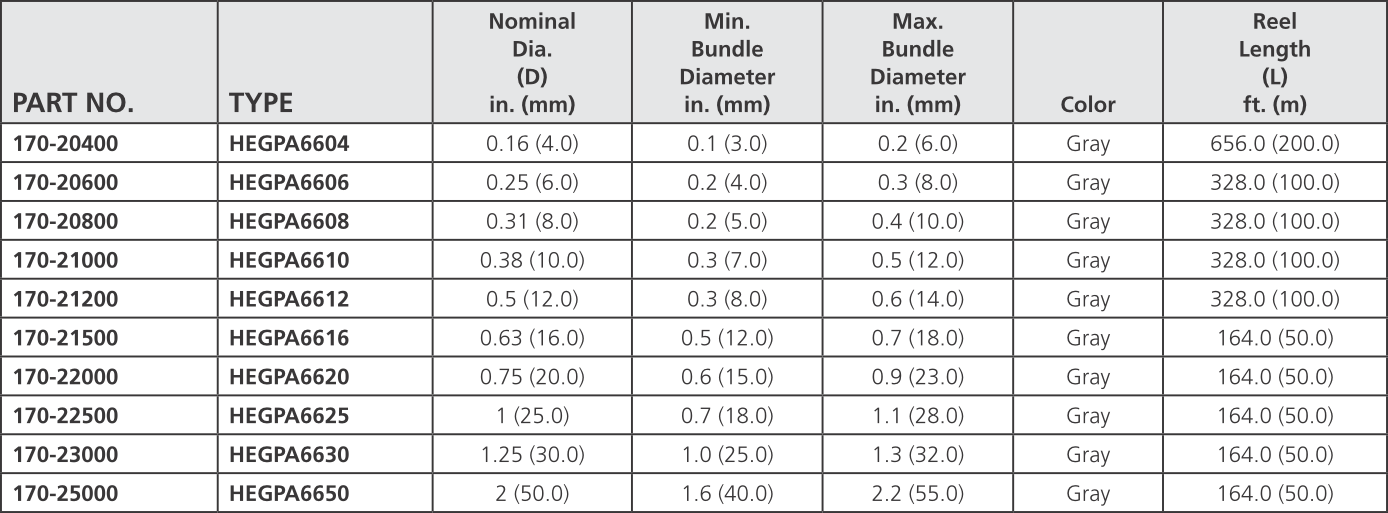

Braided Sleeving - Specialty

Expandable Braided Sleeving - Gray

A pliable yet durable nylon sleeve that protects against cuts, abrasion and excessive wear caused by repetitive motion. Used on hoses, pipes, wiring harnesses and cables installed in cars, trucks, military vehicles, trains and industrial equipment. Protects delicate wiring in engine compartments and near exhaust systems or used to organize wires and breakouts in electrical harnesses.

Features and Benefits

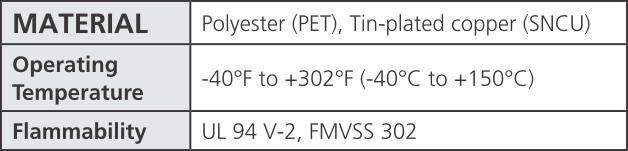

Braided Sleeving - Electromagnetic Protection

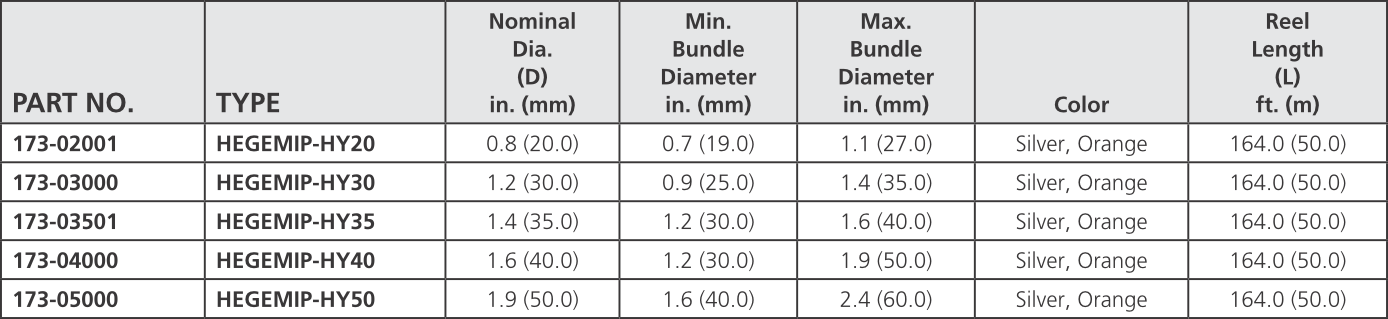

Helagaine HEGEMIP-HY

Special braided sleeving protects sensitive electronics from electromagnetic interference in hybrid and electric-powered vehicles. It won’t rupture or kink, even when flexed at sharp angles. The sleeving has a 3:1 expansion ratio.

Features and Benefits

Braided Sleeving - Specialty

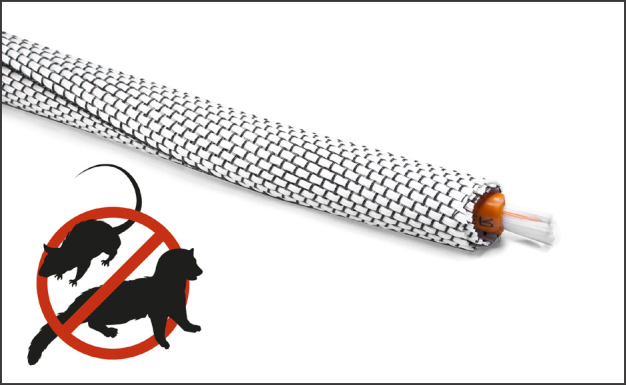

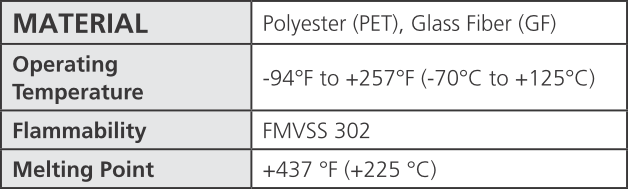

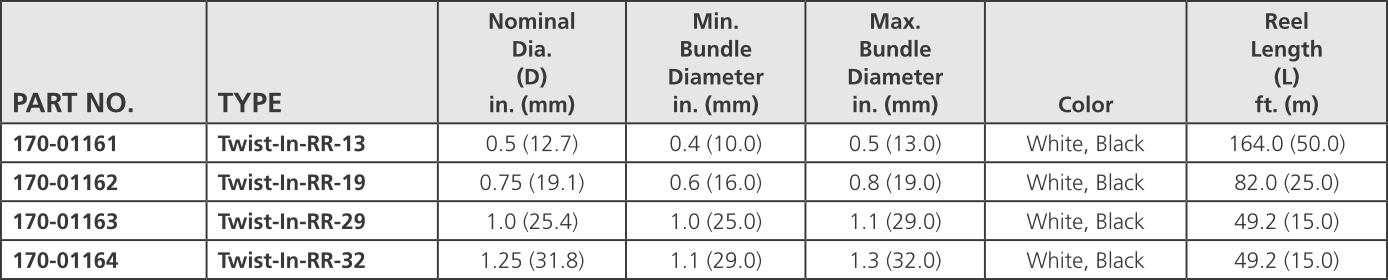

Twist-In Rodent-Repellent Wrap

Twist-In Rodent-Repellent Wrap is a self-closing fiberglass sleeving used to bundle cables and hoses and protect against rodents in infestation-prone areas such as automotive, railways, telecom, underground and waste treatment systems.

Features and Benefits

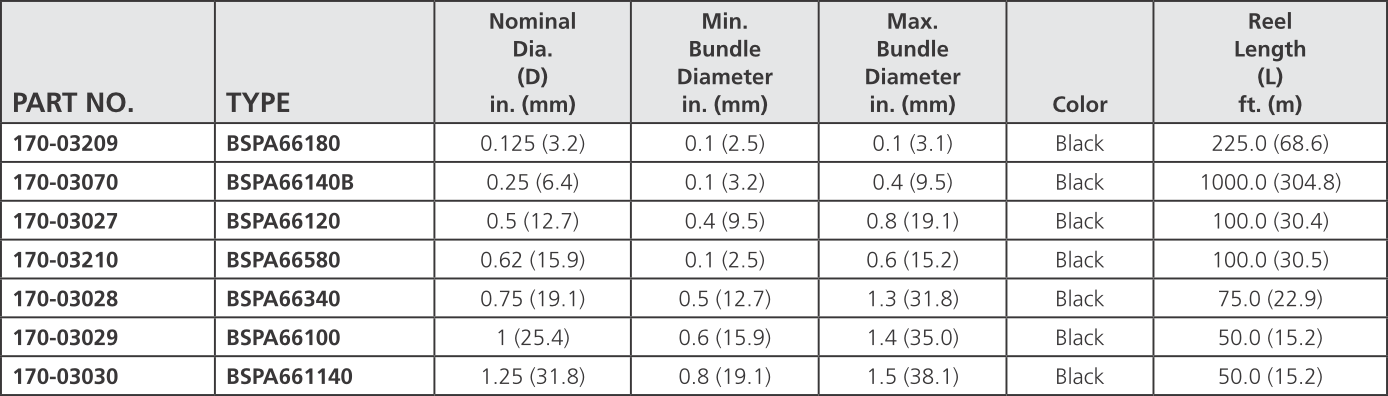

Braided Sleeving - General Purpose

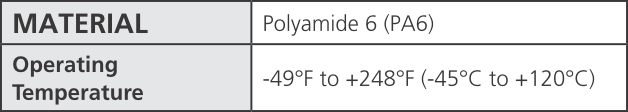

Heavy-Duty Braided Sleeving

Sleeving made of a tightly woven nylon fabric, slides onto hoses, cables and components to protect them from abrasion and environmental elements, including UV damage. Also protects surrounding surfaces from damage.

Features and Benefits

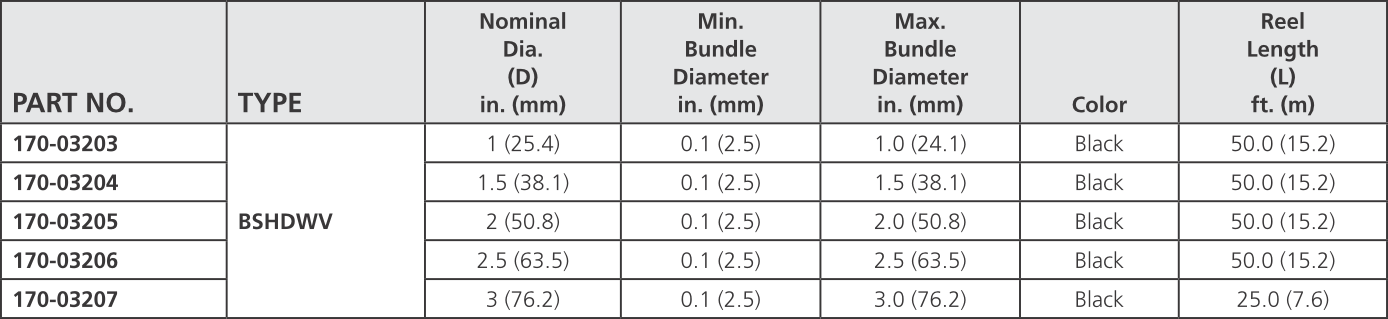

Hot Knives, Installation Tools & Accessories

Split Wrap Installation Tool

HellermannTyton offers a wide variety of application tools to assist in the installation of braided sleeving. These application tools are available in both bench mount and handheld styles.![]()

Features and Benefits

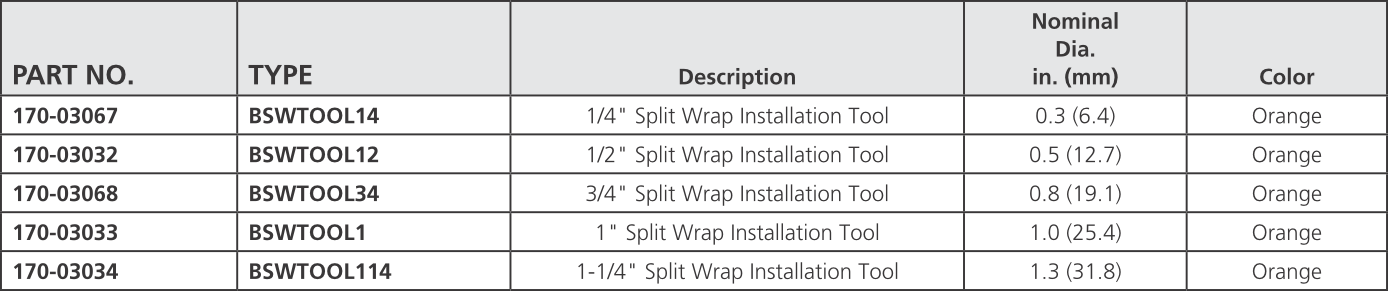

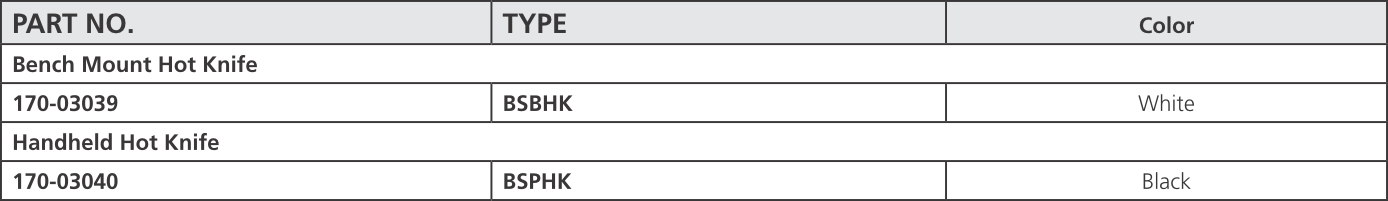

Hot Knives, Installation Tools & Accessories

Bench and Handheld Hot Knife Tools

HellermannTyton offers a wide variety of application tools to assist in the installation of braided sleeving. These application tools are available in both bench-mount and handheld styles.

Features and Benefits

###