There are many ways to mount a cable tie for your cable management. But how do you know if you are mounting in the best and safest way and considering end application or environment?

HellermannTyton’s cable management experts have created this guide to help engineers choose the best fastening solution for their application.

STEP 1: Identify the mounting options available for the application.

Review the list below and identify the mounting options that match your application.

You may find you have several options available.

- Are there existing mounting holes in the panel or can you design holes to be drilled into the surface?

- Does the area have a panel edge?

- Are studs or mounts already an option?

STEP 2: Find the fastening options that meet your application needs

A: OPTIONS FOR HOLES

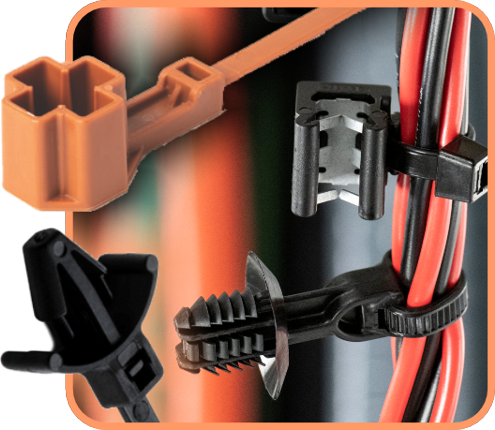

There are two options for holes: fir trees and arrowheads. Both are effective solutions for reducing installation time and speeding up the assembly line. Each brings its own set of benefits, so read through to fully understand why you would want one over the other.

Fir trees:

- Allow for larger range of panel thicknesses. The last two “branches” should be fully inserted through panel.

- Low insertion effort required while providing high extraction force.

- Discs prevent rattling in high-vibration applications, helping to reduce noise.

- Two-piece fir trees allow for servicing. If the tie needs to be cut to access the cables or tubes, the fir tree stays mounted and only the tie needs to be replaced.

- Oval fir trees prevent rotation.

- Standoff fir trees add vertical space between the mounting point and the bundle to bypass heat sources or obstructions.

- Offset fir trees add horizontal distance between the fir tree and bundle allowing for different bundle configurations or bypassing heat and obstructions.

Arrowheads:

- Require a more precise range of panel thickness than fir trees.

- Audible click to confirm full engagement.

- Discs prevent rattling in high-vibration applications, helping to reduce noise.

- Wings help stabilize and prevent rocking.

- Two-piece arrowheads allow servicing. If the tie needs to be cut to access the cables or tubes, the arrowhead stays mounted and only the tie needs to be replaced.

- Oval arrowheads prevent rotation.

- Sealing foams or rubber sealant help prevent noise and restrict water and dust ingress.

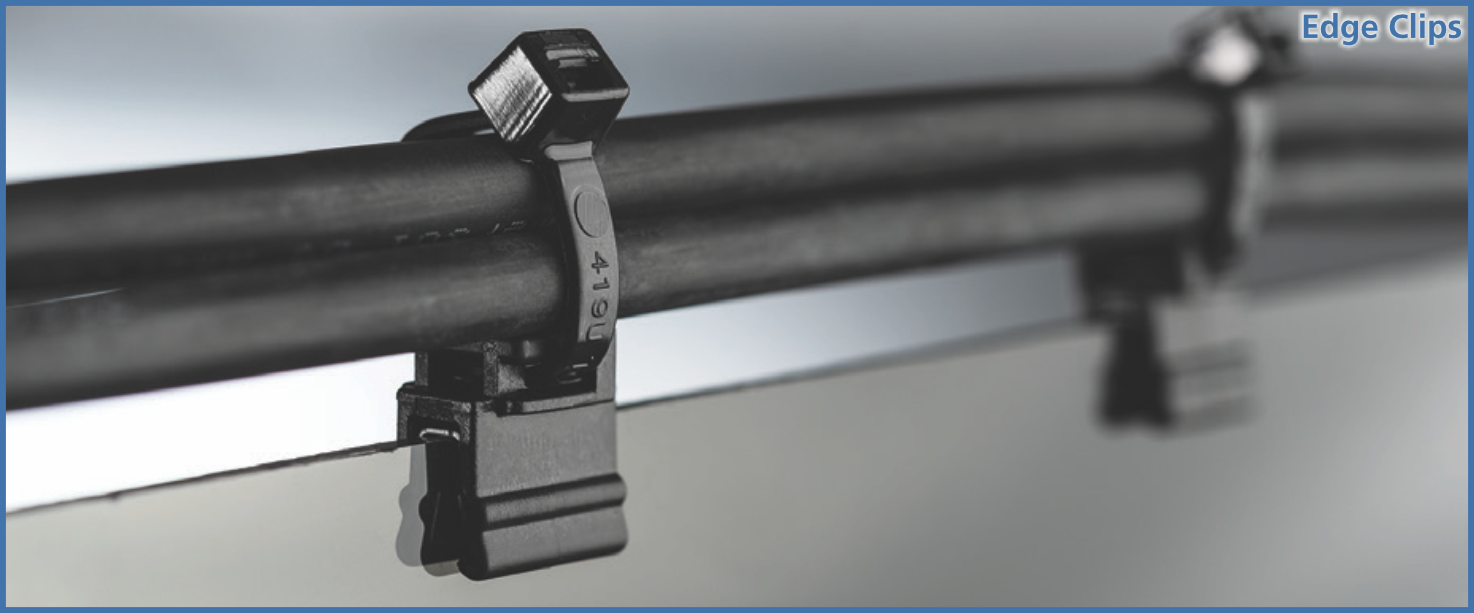

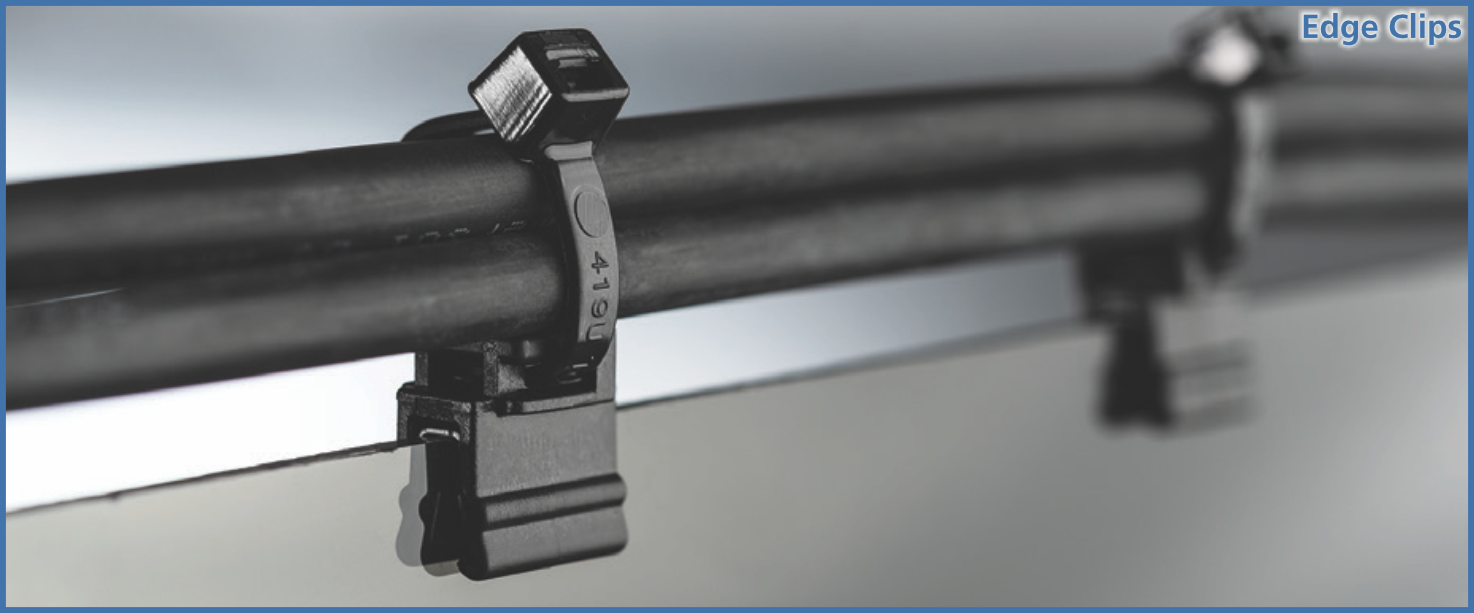

B: OPTIONS FOR PANEL EDGES

Panel edges can offer a convenient option for routing. They provide fast install time along an edge – no stud, bolt or hole required. Panel thickness is an important consideration when choosing the correct edge clip. Standard sizes are 1-3 mm and 3-6 mm. Options exist for smaller and larger panel thicknesses, but they have fewer routing orientation options. Edge clips provide options to run the bundle parallel or perpendicular to the panel edge. Additionally, different orientations route the bundle above the edge clip or to the side of it.

- Best to attach to aluminum or plastic.

- Range of panel thickness (.5 mm – 8 mm); most common 1-3 mm and 3-6 mm.

- Various orientation options.

- Product construction is plastic and metal or all metal.

- Metal is corrosion resistant.

- Two-piece options for serviceability.

* Note edge clips installed on coated or painted steel surfaces can lead to scrapping and potentially corrosion.

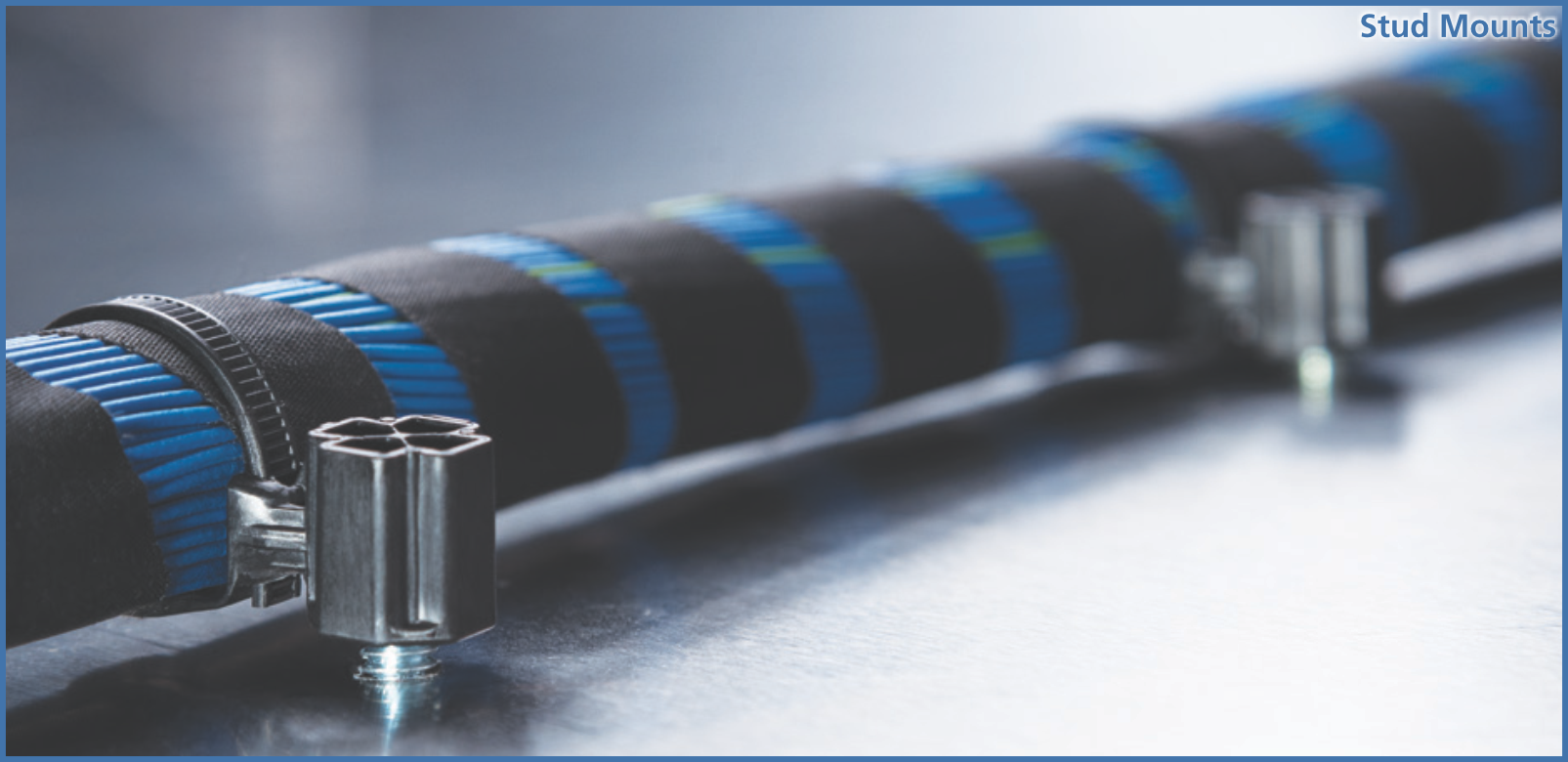

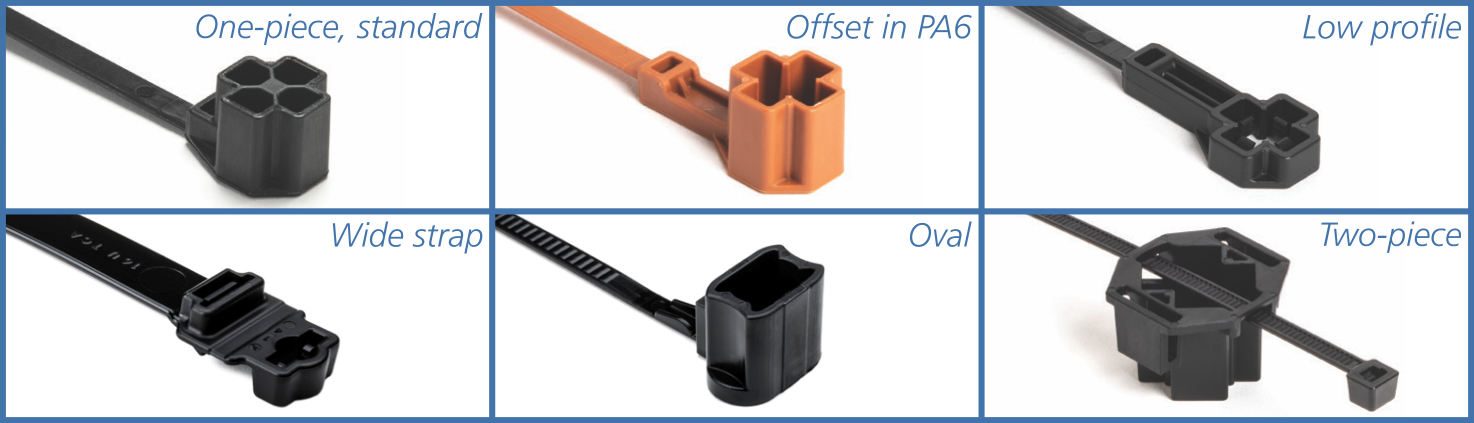

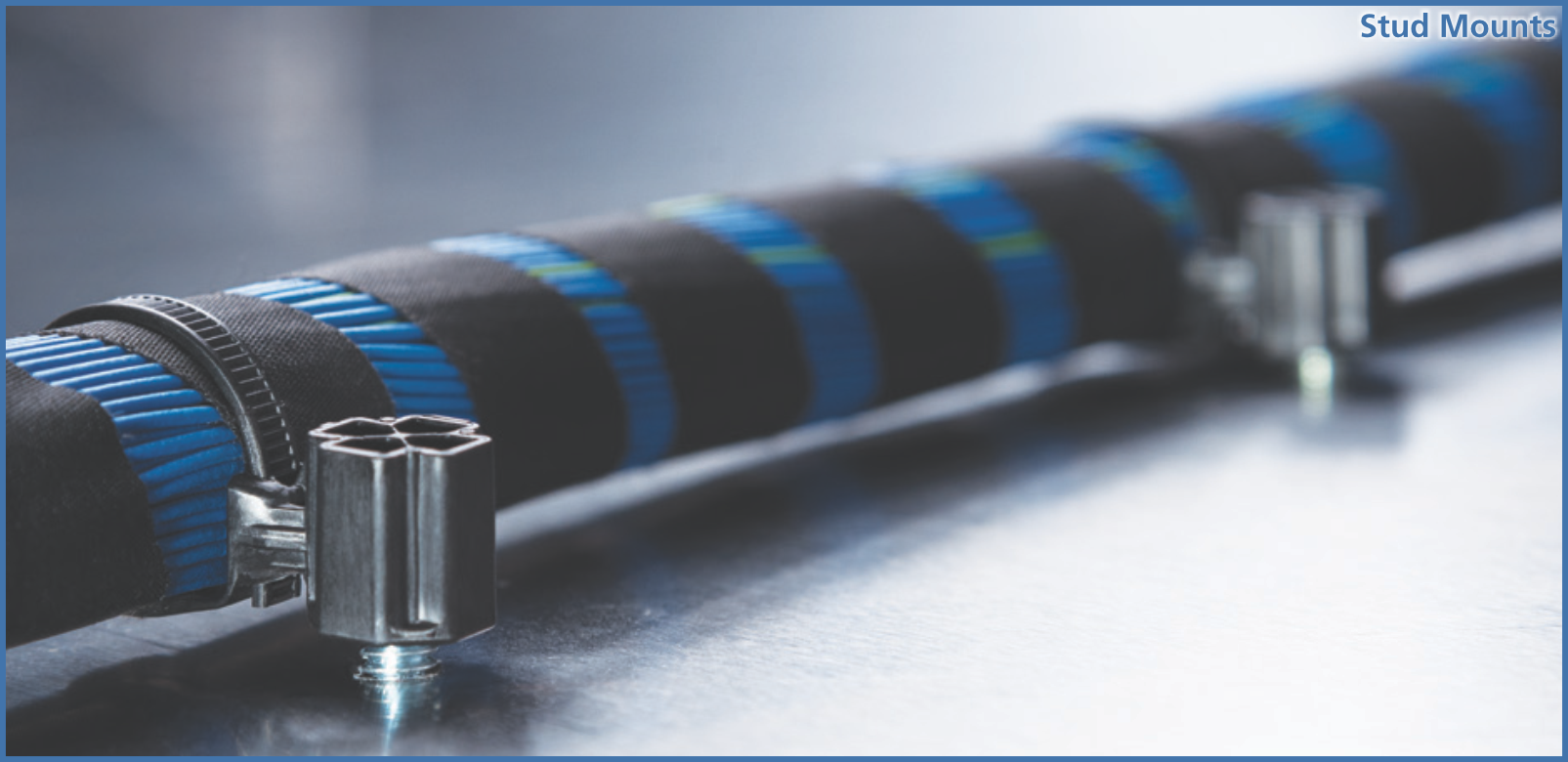

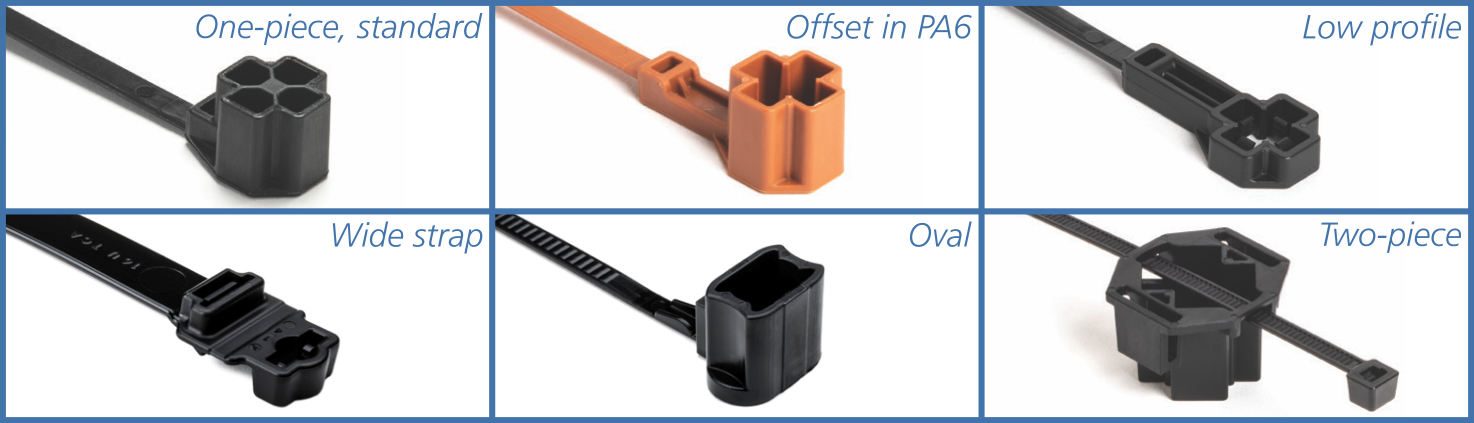

C: OPTIONS FOR STUDS OR BOLTS

Stud and bolt mounts were created as a solution for fast installation onto an existing bolt or stud. There is a line of stud mounts that perform at higher pull-off forces compared to fir trees and arrowheads, making them ideal for heavier duty applications.

- One-piece options cover bolt or stud and prevent abrasion.

- Two-piece options for serviceability.

- Offset options for routing away from bolt or stud.

- Low profile options to stack multiple stud mount ties on one stud, allowing for multiple routings.

- Oval options allow for tolerance stacking when shipping harnesses.

- High heat options in PA46.

STEP 3: Prioritize the features most important to you, based on the application and installation.

Consider environmental and performance factors:

- Is this for indoor or outdoor locations?

- Do operating temperatures extend beyond the tolerances of PA66 or 85C?

- Is this a high-vibration application?

- Will the cables, wires or parts require removal for servicing?

- Is it a heavy duty, high-vibration environment that requires higher pull-off force?

Additionally, consider installation factors such as:

- What is the installation time or assembly time?

- Will this be installed onto finished goods or shipped before final installation?

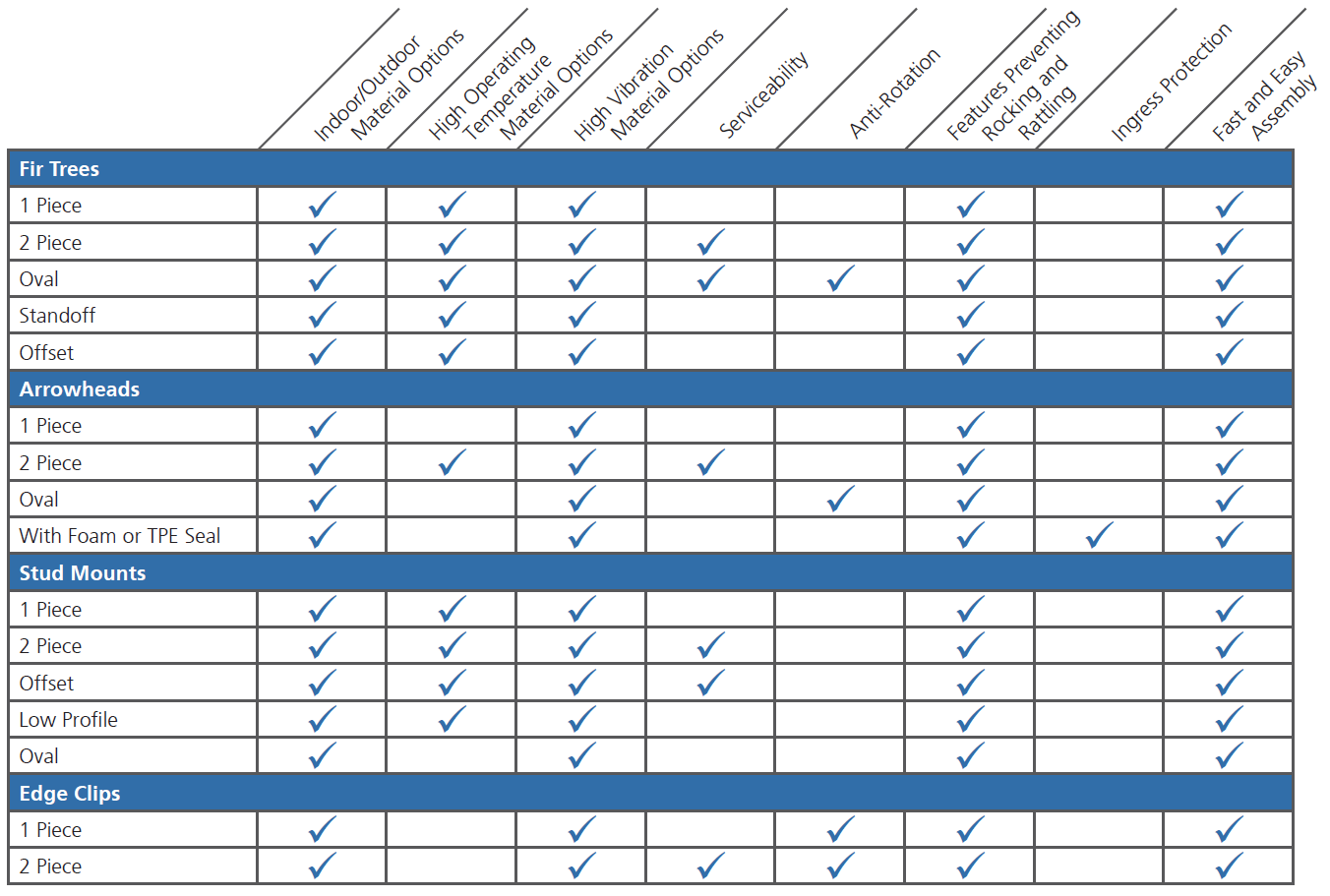

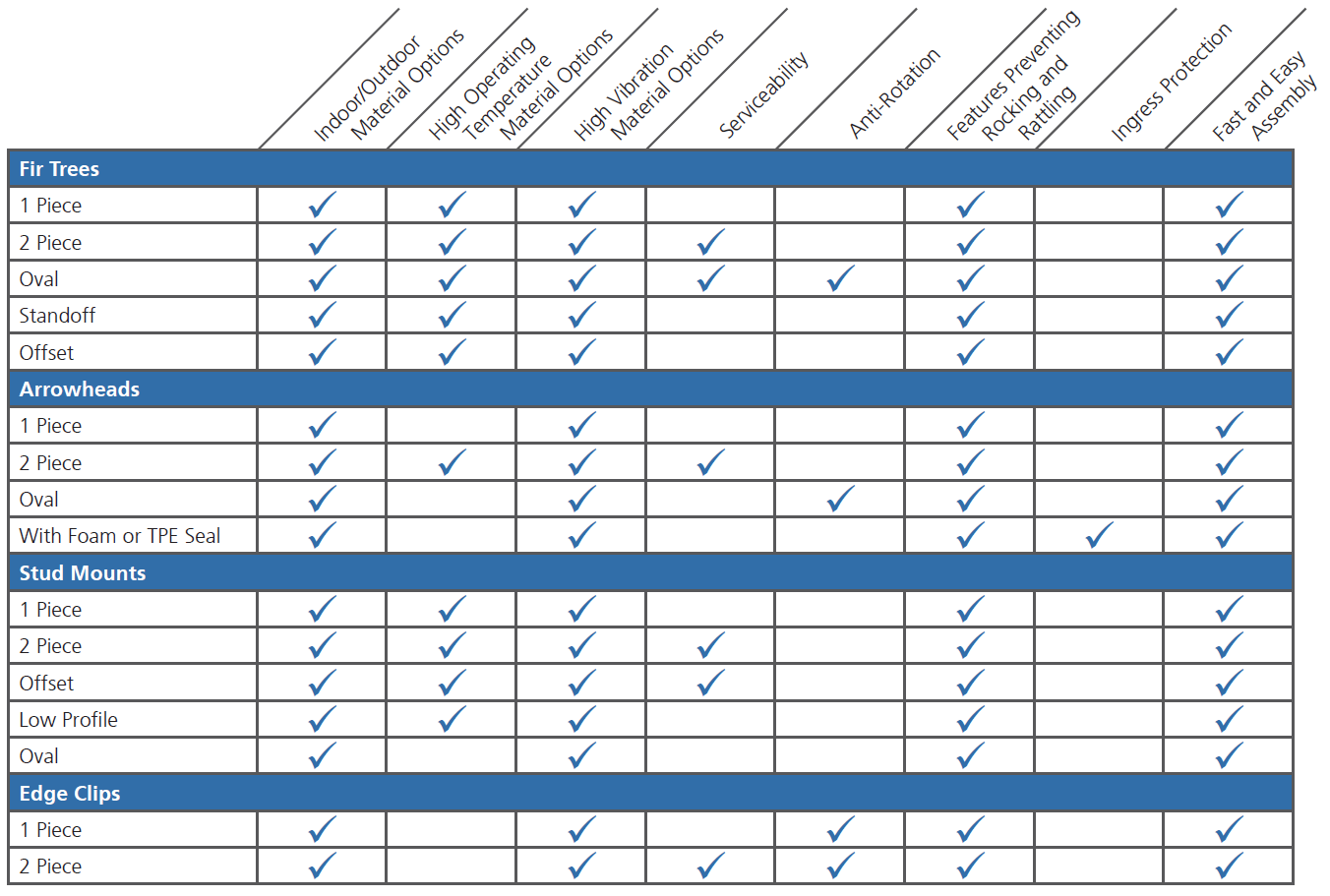

General rating of environmental and installation factors by mounting type

About HellermannTyton

HellermannTyton is a global leader in cable management, protection and identification products. Its systems and solutions are specified by major manufacturers and contractors in the OEM, automotive, heavy equipment, renewable energy and related industries.

###